Are you overwhelmed by the different types of pumps available and not sure which one to choose for your research project? Then this blog post is perfect for you.

This article will explore the differences between two popular pumps used in research: the peristaltic pump and syringe pump. We’ll look at both comparative advantages – like accuracy, convenience, cost – as well as any potential drawbacks associated with each type of pump. By the end, we hope to give you a better understanding of what these pumps can offer so that you can make an informed decision about which one best suits your project needs!

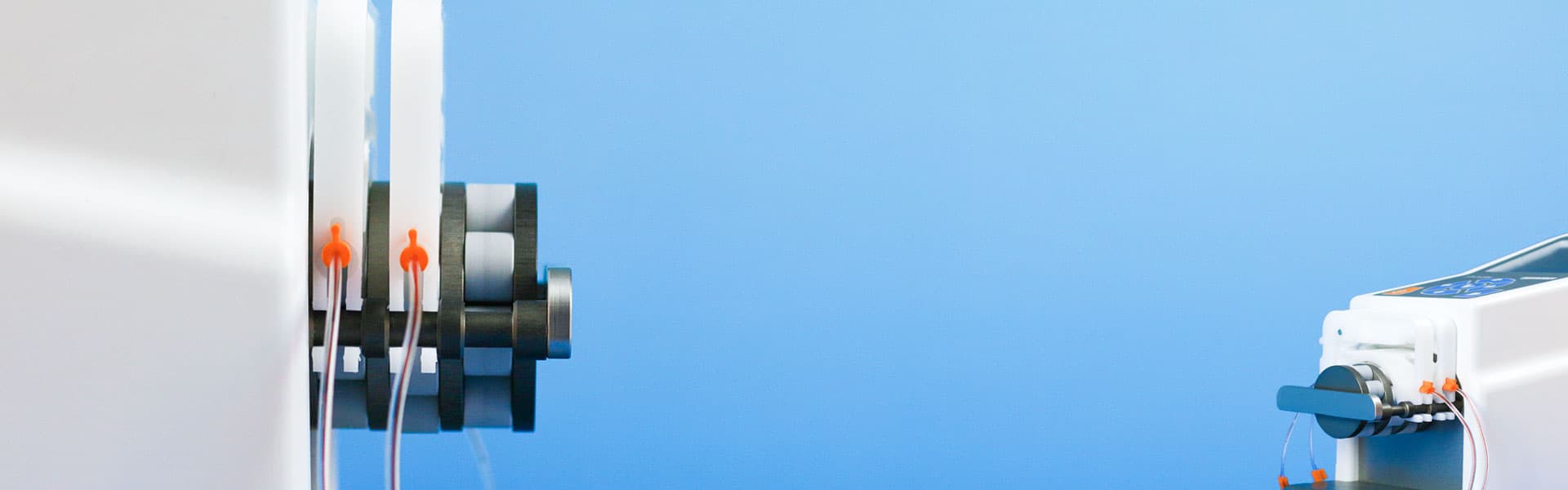

Main Differences Between a Peristaltic Pump and a Syringe Pump

| Feature | Peristaltic Pump | Syringe Pump |

|---|---|---|

| Working Principle | Uses rollers to compress flexible tubing | Uses a motor-driven plunger in a syringe |

| Fluid Contact | Fluid only contacts the tubing | Fluid contacts the syringe barrel and plunger |

| Flow Rate Range | Typically broader range | Typically narrower range |

| Flow Rate Accuracy | Lower accuracy, can be affected by tubing wear | Higher accuracy due to precise plunger movement |

| Pulsation | Pulsatile flow | Steady, continuous flow |

| Pressure Capabilities | Generally lower pressure capabilities | Higher pressure capabilities |

| Contamination Risk | Lower risk, as fluid only contacts the tubing | Higher risk, as fluid contacts syringe components |

| Maintenance | Requires regular tubing replacement | Requires periodic calibration and plunger checks |

| Applications | Fluid transfer, media circulation, filtration | Microfluidics, drug delivery, sample injection |

| Cost | Generally lower initial cost and higher maintenance cost | Higher initial cost and lower maintenance cost |

When selecting a pump for a specific application, consider factors such as the required flow rate, pulsation, and shear sensitivity. For instance, a peristaltic pump might be more suitable for cell culture experiments due to its gentle, low-shear pumping action, while a syringe pump might be preferred for applications requiring precise fluid delivery, such as drug infusion or microinjection.

To evaluate and compare these pumps, consider not only their cost but also size, maintenance requirements, ease of use, and integration into your microfluidic system. Assess whether the pump’s features align with your application needs, available space, and budget constraints. By carefully considering these factors, you can select the most appropriate pump for your microfluidic system, ensuring reliable and efficient performance across various applications.

How to Choose Between a Peristaltic Pump and a Syringe Pump: A Cheat Sheet 🧠

Step-by-Step Guide: How to Choose the Right Pump

- Identify your application requirements: Consider factors such as fluid type, flow rate, pulsation, and shear sensitivity.

- Evaluate flow rate and accuracy needs: If your application requires precise fluid delivery, a syringe pump may be more suitable. For a wider range of flow rates and fluid types, consider a peristaltic pump.

- Consider ease of use and maintenance: Peristaltic pumps typically require less maintenance due to their non-contact pumping mechanism. Syringe pumps, however, may require more frequent refilling and cleaning.

- Assess compatibility with fluids and tubing materials: Ensure the pump you choose is compatible with the fluid you’ll be using and the tubing material required for your application.

- Compare costs and other factors: Take into account the cost, size, and integration capabilities of each pump to make an informed decision.

Typical specifications of syringe pumps

| Info | Accuracy | Reproducibility | Pulsatility |

|---|---|---|---|

| Syringe Pump | Down to ± 0.25% | Down to ± 0.05% | Almost pulseless flow rate |

Typical specifications of peristaltic pumps

| Info | Accuracy | Reproducibility | Pulsatility |

|---|---|---|---|

| Peristaltic Pump | Down to ± 1% | Down to ± 0.5% | Pulsating flow rate (refer to article) |

Microfluidics Applications

| Application | Syringe Pump | Peristaltic Pump |

|---|---|---|

| Droplet generation | Possible | Difficult |

| Liposome Nanoparticle (LNP) synthesis | Possible | Difficult |

| Organ-on-chip (OOC) | Possible | Possible |

| Recirculating fluids (for OOC application or 3D cell-culture) | Difficult | Easy |

| Enhanced Oil Recovery | Possible | Difficult |

| High-Pressure Experimentation | Possible | Difficult while keeping a good precision |

By understanding the key features, advantages, and disadvantages of both peristaltic pumps and syringe pumps, and following the step-by-step guide provided in this cheat sheet, you can make an informed decision on which type of pump best suits your specific microfluidic application 😉