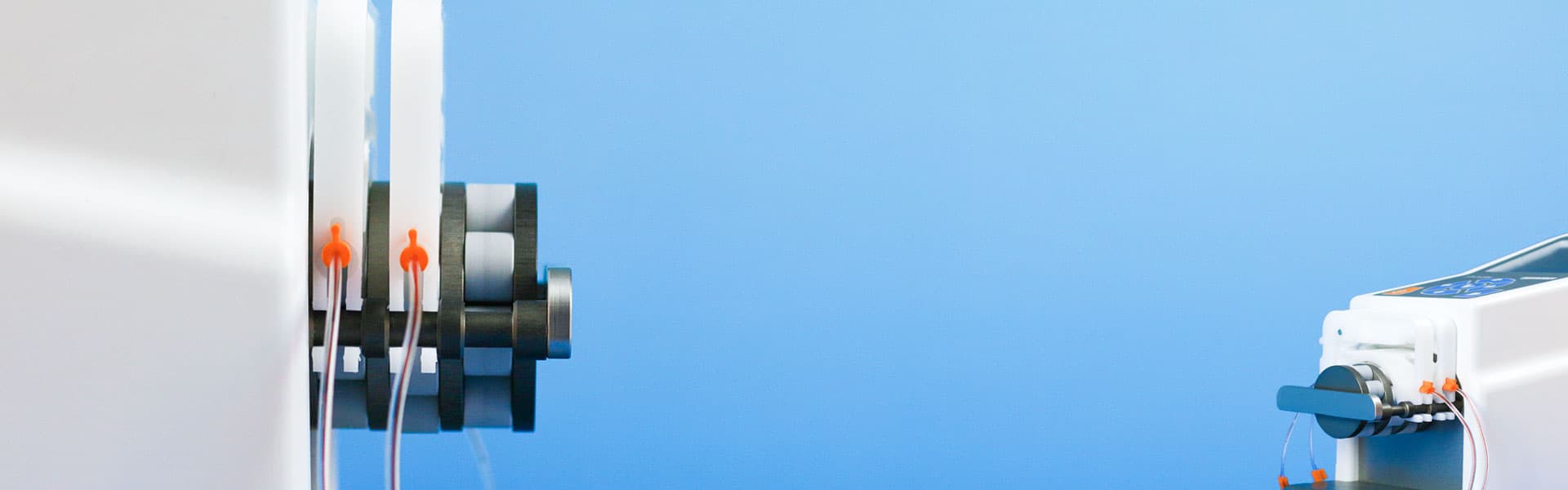

Peristaltic pumps have become essential tools in scientific research, medical diagnostics, and industrial processes, providing precise fluid control with minimal contamination risk.

Among the diverse range of peristaltic pumps available, Longer pumps (from Longer Precision Pump Co., Ltd) have gained prominence for their reliability, precision and versatility.

Their peristaltic pumps can be controlled remotely from a computer, offering more flexibility and convenience, especially for running complex pumping programs with loops, pauses, and varying flow rates.

In this comprehensive guide, we’ll explore the communication control of Longer peristaltic pumps, focusing on remote operation, command strings, and interfacing options. While we won’t delve into the intricate details of specific communication protocols for specific Longer pumps, this overview will provide a solid foundation for users seeking to interface with Longer pumps in their applications.

From this blog post, you can navigate to the detailed guides for control methods of specific Longer pumps using either Matlab or Python and explore a wide range of Longer pump control tutorials:

- How to Control the Longer BT100-1L Pump via Matlab ?

- How to Control the Longer BT100-1L Pump via Python ?

- How to Control the Longer L100-1S-2 Pump via Matlab ?

- How to Control the Longer L100-1S-2 Pump via Python ?

- How to Control the Longer WT600-2J Pump via Matlab ?

- How to Control the Longer WT600-2J Pump via Python ?

TABLE OF CONTENTS

Longer RS485 Communication Protocol

The ability to interface and communicate with the Longer peristaltic pumps programmatically opens up avenues for automation, integration into larger systems, and facilitates incorporation into experimental setups. Whether you are involved in laboratory automation, fluid handling systems, or any application requiring precision and programmability, mastering the Longer communication protocols is fundamental.

The communication control is based on the Longer RS485 protocol, which is a serial communication protocol that allows you to send commands and receive responses from the pump. Therefore, to communicate with a Longer peristaltic pump, you will need the following:

- A corresponding Longer peristaltic pump with a pump head and a tubing of your choice

- A RS485 control module that plugs into the DB15 port on the rear of the pump

- A DB15 connector that is wired to the RS485 control module

- A serial cable that connects the RS485 control module to your computer or device

- A programming platform (Matlab or Python in the case herein)

- A basic understanding of the data format, command format, and pdu format of the Longer communication protocol corresponding to the working pump

To control the pump by an external computer through RS485 communiacation interface, first the DB15 connector should be wired then plugged on the DB15 port on the rear of the pump. Second, the pump should be turned on and, depending on the pump, the control module should be enabled by using the keypad or the adjusting knob on the pump front.

Data Format

While for some pumps (e.g. BT100-1L, L100-1S-2) it is possible to remotely control the start/stop, running direction, speed and flow rate of the pump by sending commands to it, it is only possible to control the rotation speed for other pumps (e.g. WT600-2J).

Moreover, while some pumps(e.g. BT100-1L) have one single defined set of communication parameters, some others (e.g. L100-1S-2) have different communication parameters that could be set through the keypad on the pump front or through the command.

The data format is therefore defined as follows :

- 1 start bit

- 8 data bits

- Parity (no parity, even parity, odd parity, depending on the pump)

- Stop bit (1 stop bit or 2 stop bits depending on the pump)

The baud rate may be set as a fixed and unchangeable value for some pumps (e.g. 1200 bits/s in the case of a BT100-1L), whereas for other pumps (e.g. L100-1S-2), it can be selected from a set of different values.

🚨🚨 What’s crucial is that the parameters specified in the command must align with the parameters of the pump.

Control Command Format

The command format is consistent across all series of Longer pumps and is defined as follows:

- a start flag: every command string is preceded with the start flag E9

- the pump address: from 1 to 30; only the pump with the address designated in the command string will respond and execute the command

- the length of the pdu that depends on the application required from the pump

- the protocol data units (pdu) that depends on the application required from the pump

- a frame check sequence (fcs): obtained by calculating the XOR of the pump address, the length of the pdu and the pdu itself (check our online frame check sequence XOR calculator)

Different applications can be requested from the pump, depending on the pump series. The various hexadecimal command string formats used to communicate with Longer pumps are explained separately, with the communication control of each Longer series of pumps detailed in individual blog posts.

While these guides will focus on specific Longer pump models: the BT100-1L, the L100-1S-2 and the WT600-2J, the principles discussed can be applied to a broader range of Longer pumps. Whether you are working with one of the beforementioned pumps or other models, understanding the fundamentals of communication control will empower you to adapt and implement these concepts across the Longer product line.

🚨Do not hesitate to use our user-friendly online command string generator to effortlessly generate precise control command strings for your Longer peristaltic pumps.

Serial Communication Using Programming Platforms

A control command string is most of the times obtained after some calculations and conversions. It is therefore important to prepare all the needed commands before starting the external control of the pump.

Moreover, it is easier to have the control command strings written and communicated to the pump via a set of already prepared codes, using programming platforms such as Matlab and Python, than to write and send a command string every now and then to the pump via a terminal emulator.

These programming platforms allow not only an easier communication with the pump, but also, an easier external communication with a bus of pumps and allow writing a pumping program with loops, pauses and varying speeds.

Our guides delve into the specifics of utilizing Python and Matlab and serve as a quick introduction on how to communicate with Longer pumps: from establishing a connection, opening the serial port and initializing communication protocols to writing and executing control commands.

Real-world examples and code snippets will guide you through the process, helping you tailor the implementation to your specific requirements.

Conclusion

Stay tuned for in-depth tutorials, case studies and insights that will further enhance your mastery of Longer peristaltic pumps. Discover the full range of possibilities, from enhancing precision in fluid handling to integrating Longer pumps into complex automated workflows.

🔓 Unlock the full potential of your Longer peristaltic pumps with effective communication control ! 💪🏼

📧 If you have any questions or feedback, please feel free to contact us at support@darwin-microfluidics.com.

Control Command String Generator for Longer Peristaltic Pumps

[…] in, pump up the excitement and make your Longer pump control more accessible and intuitive than ever before […]