Over the last few years, there have been major developments in organ-on-chip (OoC) platforms. Yet, there is no ‘one-fits-all’ model, and probably will never be considering the variety of applications for which those devices can be used. Thus, it is worth taking into account several key parameters when choosing or developing an Organ-on-Chip platform to get a system best suited to the scientific question to answer.

If you’d like to find out more about organ-on-chip, read our review: Organ-On-Chip: a general overview.

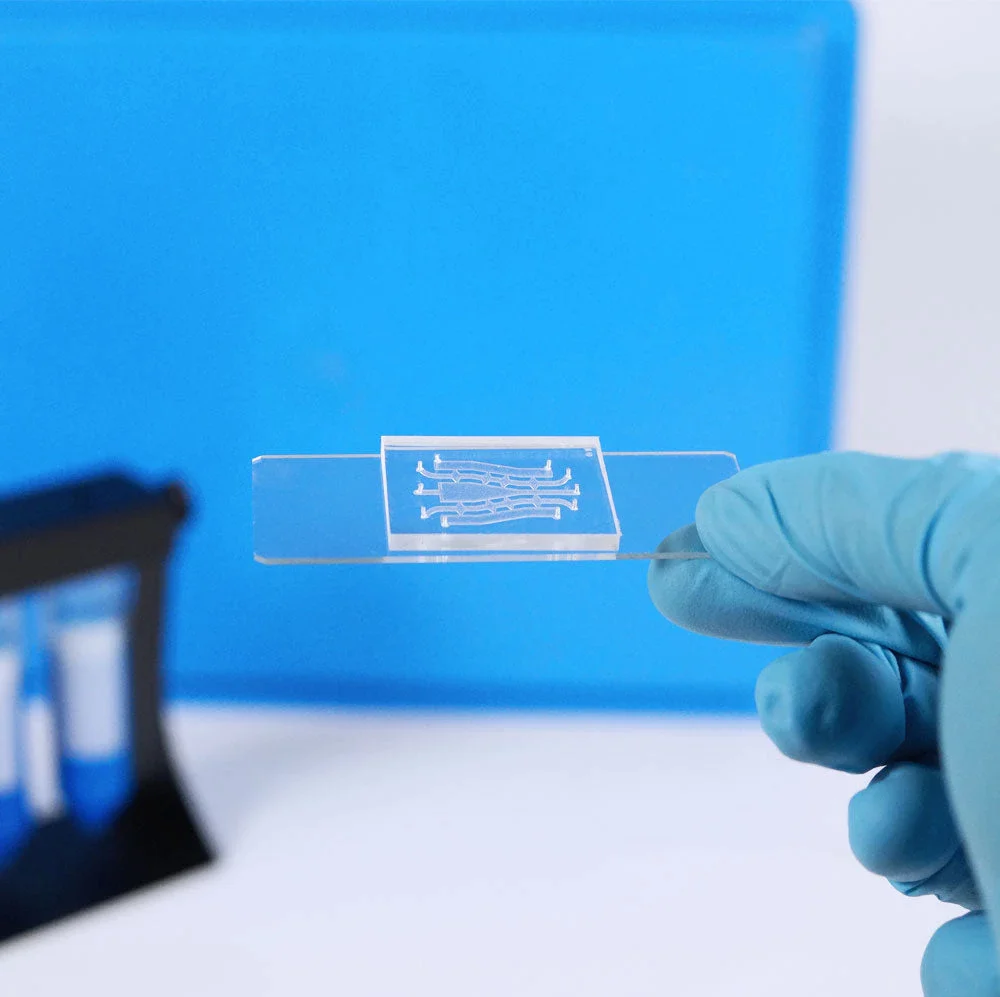

Design of the Organ-On-Chip device

The design of the chip is a critical element to consider when developing an OoC model. It depends on the specific application for which the device will be used. This will determine geometrical parameters such as the number, shape, and dimensions of channels, the number of inlets/outlets, and the presence of culture chambers, ports, or any other elements needed to fulfill the intended study. On the biological side, the cell number, density, and fluid volume should also be taken into account during the design process. Proper definition of these elements will contribute to an accurate physiological modeling of the organ/cells under study.

Another arising question with implementing an OoC model is the need for multiplexing – having multiple designs on a single platform – which will often define the format of the platform. Having multiple replicates on the same device can be a great time saver and even necessary, in particular for drug testing purposes.

The design of the platform should also take into account the parameters the researcher wants to test/measure with the platform. Some readouts relevant to the study can require access to specific parts of the chip to perform analyses. For example, to identify a specific biomarker it can be useful to be able to collect effluents several times over the course of the study and thus plan to have a special port for easy media collection. Also if any analysis needs to be performed on the cells/tissue at the end of the experiment, it is important to be able to recover the cells/tissue from the platform.

Finally, more logistic parameters such as footprint, use in an incubator, circulation of flow, and others, can influence how the platform is going to be used and thus its design.

How to chose the right material for your Organ-On-Chip device?

The choice of material is of great importance, yet it is not that easy to find a material that will meet all the experiment requirements and there might be compromises to make in that selection. Among the parameters of this selection are biocompatibility, of course, but also the microfabrication strategy chosen or available, the endpoints the model needs to achieve, the stiffness of the substrate, the permeability to gases, considerations regarding mass production, and many others.

The main materials for Organ-On-Chip devices

Currently, no perfect ideal material exists for OoC devices. In general, it is preferred that the material chosen is not toxic for cells, is permeable to gases, and allows optical observation. Several material options are available each presenting advantages and drawbacks in terms of physico-chemical, biological, economic, or practical parameters.

From Campbell et al., 2021 – Green: good, yellow: medium, red: bad

The most used material for microfluidic chips and OoC is PDMS (Polydimethylsiloxane) mostly due to its ease of use, low price, and optical transparency. It also presents a high permeability which can be both an advantage and a drawback. While it allows proper oxygen supply to cell cultures, it can also interfere with the metabolism of drugs or the production of metabolites by tissues, with a higher risk of small molecules of interest being absorbed in the polymer matrix.

Other materials commonly used in chip fabrication are thermoplastics. Their low cost, low absorption, and optical transparency properties are important advantages for OoC (mass) production. However, the rigidity of thermoplastics can be an issue for physiological modeling. In the body, tissue stiffnesses can go as low as a few kPa for adipose tissue or brain as compared to the few GPa of common thermoplastics. It can also be challenging to create complex geometries when working with thermoplastics which can thus be a limitation for the chip design.

Another material being used for OoC devices is glass which presents the advantage of being highly transparent, inert, biocompatible, and having low autofluorescence. The surface of glass can also easily be modified to tune cell adhesion. Yet, glass devices are much more fragile and expensive, in addition to a more laborious fabrication process.

Material sterilization & Surface treatment

Once a material has been chosen, questions regarding its sterilization or functionalization can arise.

Sterilization might be necessary to avoid microbial contamination of the device which could interfere with the study performed and its results. Many sterilization techniques exist such as autoclaving, UV exposure, ethanol treatment, gamma irradiation, or ethylene oxide treatment. All of these methods cannot be used with all materials cited above. For example, while it is safe to autoclave polycarbonate (PC), it might not be the case for PMMA. It is thus important to choose the appropriate sterilization technique to prevent damaging the selected material.

Surface treatment can also be a necessary step in the OoC device development for several reasons: to ensure biocompatibility, and to enhance or prevent cell adhesion. Here again, several techniques can be available to achieve such functions and compatibility with the chip material but also the cells/tissues is required.

References:

- Scott B. Campbell, Qinghua Wu, Joshua Yazbeck, Chuan Liu, Sargol Okhovatian, and Milica Radisic – ACS Biomaterials Science & Engineering 2021 7 (7), 2880-2899 – DOI: 10.1021/acsbiomaterials.0c00640

- Toepke Michael W., and David J. Beebe. “PDMS Absorption of Small Molecules and Consequences in Microfluidic Applications.” Lab on a Chip, Nov. 2006. The Royal Society of Chemistry, https://doi.org/10.1039/b612140c

- Leung C.M., de Haan, P., Ronaldson-Bouchard, K. et al. A guide to the organ-on-a-chip. Nat Rev Methods Primers 2, 33 (2022). https://doi.org/10.1038/s43586-022-00118-6

- Yanping Wang, Yanfeng Gao, Yongchun Pan, Dongtao Zhou, Yuta Liu, et al., Emerging trends in organ-on-a-chip systems for drug screening, Acta Pharmaceutica Sinica B, Volume 13, Issue 6, 2023, Pages 2483-2509, ISSN 2211-3835, https://doi.org/10.1016/j.apsb.2023.02.006.