The Bartels BP7 piezoelectric micropumps from Bartels Mikrotechnik represent a significant advancement in microfluidic technology, offering a compact and efficient solution for handling liquids and gases. Developed with the versatility to perform across various industries and applications, from moving diagnostic samples through a microfluidic device to mixing solutions, these micropumps stand out for their superior performance in confined spaces and low-power environments.

In this blog post, we will explore the numerous advantages of the BP7 micropumps and why they have become a popular choice in modern fluidic systems, and explain their operational mechanics and functionality.

From this general blog post, you can navigate to detailed guides on BP7 pumps discussing various topics related to them, including:

What is the BP7 Micropump and How Does it Work?

The Bartels BP7 micropump, an improvement over its predecessor, the mp6 micropump, is a compact piezoelectric pump engineered to provide precise fluid control in various applications. Using piezoelectric actuators to generate mechanical motion, the BP7 micropump can efficiently handle both liquids and gases, with the ability to handle flow rates of up to 14 mL/min for liquids and 35 mL/min for gases. Its compact size and lightweight design make it ideal for space-constrained applications while offering the precision and control necessary for high-performance fluid management.

Key Components of the BP7 Micropump

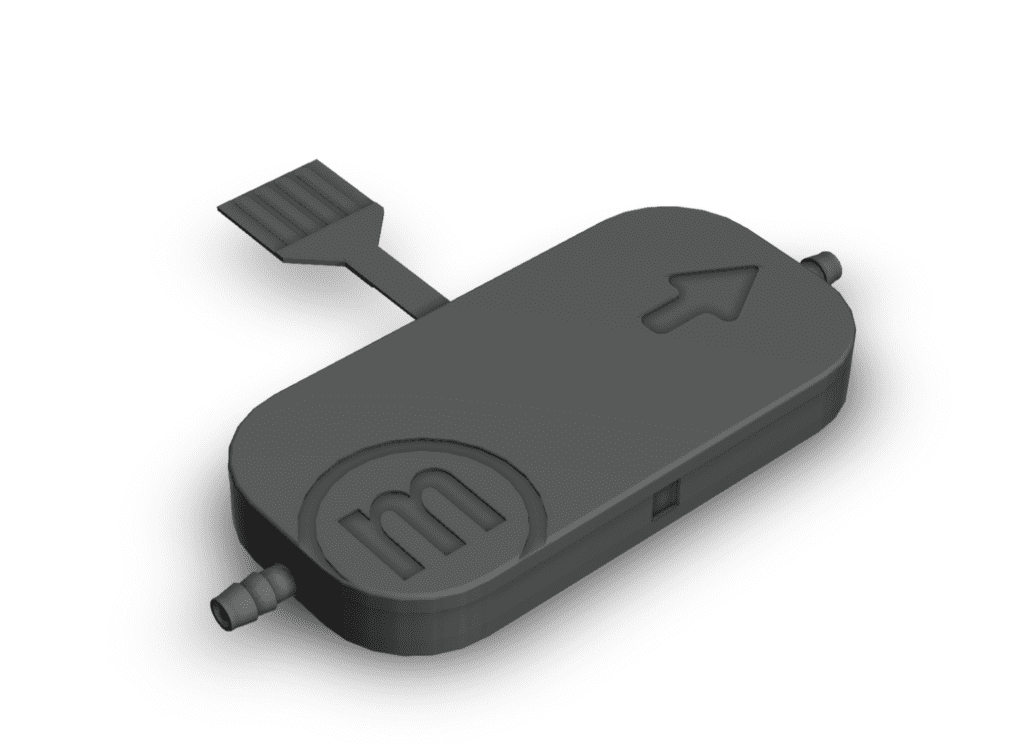

At the core of the BP7 micropump, designed by Bartels Mikrotechnik, are several key components that contribute to its reliable operation:

- Piezoelectric Actuator: The heart of the BP7 micropump is its piezoelectric actuator, a critical element responsible for driving fluid flow. When an electric voltage is applied, the piezo actuator deforms, causing the diaphragm to move and displace fluid through the pump.

- Diaphragm and Membrane: The BP7 micropump is a positive displacement membrane pump, which means it uses a flexible membrane that deforms to move fluids. The movement of the diaphragm, controlled by the piezoelectric actuator, creates pressure that moves liquids or gases through the pump chambers.

- Check Valves: The BP7 incorporates passive check valves to regulate the direction of fluid flow. These valves prevent backflow, ensuring that the liquid or gas flows in one direction only.

- Body Material: The pump’s housing is constructed from polyphenylsulfone (PPSU), which is a chemically resistant polymer allowing for the BP7 to operate reliably in various environmental conditions.

- Simplified Fluid Path: A single-material fluid path minimizes the risk of contamination and increases compatibility with sensitive liquids and gases.

For a clearer understanding of the BP7 micropump’s construction, below is a video demonstrating its assembly process and highlighting the key components and how they fit together.

Working Principle of the BP7 Micropump

The BP7 micropump operates on the principle of piezoelectric displacement, which involves converting electrical energy into mechanical motion. Central to this process is the piezoelectric actuator. When a voltage is applied to the piezoelectric element, it deforms, causing a mechanical shift in the diaphragm within the pump. This deformation creates a pressure differential in the pump chamber, driving the fluid—either liquid or gas—through the system.

As the diaphragm moves, it displaces the fluid inside the chamber, pushing it in one direction. The check valves ensure that the fluid moves in the intended direction without backflow. These passive check valves open and close automatically based on the pressure generated by the diaphragm’s movement, allowing fluid to enter and exit at precise intervals.

The process is highly repeatable and can be finely controlled by adjusting the applied voltage and frequency to the piezoelectric actuator, which allows for the control of the fluid flow rate.

For a clearer understanding of the BP7 micropump’s operation, the video below explains its working principle. This visual guide showcases how the piezoelectric actuator, diaphragm, and check valves work together to precisely control fluid flow.

Types of BP7 Micropumps

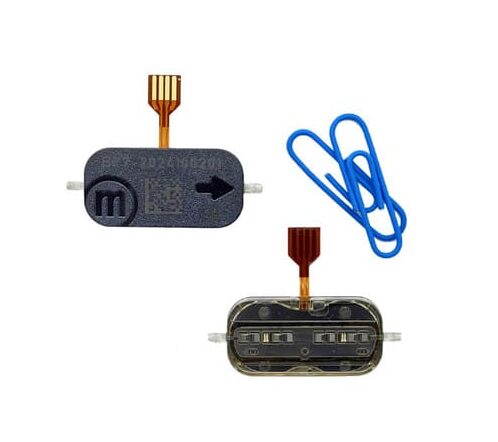

The Bartels BP7 pump series features two innovative models designed to meet diverse integration needs in fluidic systems: the BP7 Tubing and the BP7 Mounting.

BP7 Tubing Micropumps

The BP7 Tubing is designed for easy integration into fluidic systems. It features side connectors specifically optimized for tubing connections, simplifying the setup process. It is also best paired with Tygon LMT-55 tubing, recommended for its inner diameter of 1.3 mm.

BP7 Mounting Micropumps

In contrast, the BP7 Mounting is designed for applications where space-saving is essential. This model connects directly to fluidic manifolds, eliminating the need for tubing and resulting in a more compact setup. It is particularly suited for customers looking to optimize space in their microfluidic systems while still ensuring high performance.

Technical Specifications of the BP7 Micropump

The key technical specifications of the BP7 micropumps, including both the BP7 Tubing and BP7 Mounting models, are outlined in the table below. These specifications highlight the pump’s capabilities in handling liquids and gases with precision, as well as its durability and energy efficiency.

| Parameter | Specification |

|---|---|

| Pump Type | Piezoelectric Diaphragm Pump |

| Dimensions (without connectors) | 30 x 15 x 3.8 mm (1.1811 x 0.5906 x 0.1498 in.) |

| Typical Dynamic Range Flow Rate (Water) | 0 - 14000 μl/min1 |

| Typical Dynamic Range Pressure (Water) | 0 - 500 mbar1 |

| Typical Dynamic Range Flow Rate (Air) | 0 - 35000 μl/min1 |

| Typical Dynamic Range Pressure (Air) | 0 - 140 mbar1 |

| Operating Temperature | 0 - 70°C |

| Internal Volume | ~ 30 μl |

| Weight | 2 g |

| Burst Pressure | 1.5 bar |

| Lifetime | 5000 h2 |

| Power Consumption | ~ 50 mW2 |

| IP Code | IP333 |

| Material in Contact with Media | Polyphenylsulfone (PPSU)4 |

1 Typical values can vary under application conditions.

2 Conditions: settings mp-labtronix: 100 Hz, 250 V, SRS.

3 Can be changed to IP44.

4 Other materials available on request.

Why Choose a Bartels BP7 Micropump?

The Bartels BP7 micropump offers a range of advantages that make it an excellent choice for fluid handling in microfluidic systems. Whether for medical devices, diagnostics, or industrial applications, its combination of performance, reliability, and ease of integration stands out.

- Versatility in Handling Liquids and Gases: Capable of efficiently managing both liquids and gases, the BP7 is ideal for applications requiring diverse fluid handling without the need to switch pumps.

- Compact and Lightweight: With dimensions of just 30 x 15 x 3.8 mm and weighing only 2 grams, the BP7 can be easily integrated into space-constrained devices.

- Low Power Consumption and Quiet Operation: Consuming only 50 mW of power and operating with minimal noise, the BP7 is highly energy-efficient, and suitable for environments where quiet performance is necessary.

- Minimal Maintenance: Fewer moving parts reduce wear and tear, leading to low maintenance needs and longer pump life, up to 5000 hours of continuous operation.

- Fast Response and Precision: The piezoelectric actuator ensures rapid response times and precise flow control.

- Easy Integration: Available in two versions—BP7 Tubing and BP7 Mounting—the pump is designed for easy integration into different fluidic systems, whether using tubing or direct manifold connections.

- Fast Response Time and Low Internal Volume: The micropump’s fast response time and small internal volume (approximately 30 µL) enable precise control and quick operation.

- Quality and Cost-Effectiveness: Manufactured using injection molding, the BP7 ensures high-quality, batch-to-batch reproducibility with a significantly lower cost compared to other pumps.

With these features, the BP7 micropump is an efficient, durable, and versatile solution for modern fluidic systems.

Applications of BP7 Micropumps

The BP7 micropumps are suitable for a wide range of applications across various industries including:

- Point-of-Care Medical Devices: BP7 micropumps ensure accurate fluid delivery in portable diagnostic equipment and medical dosing devices.

- Gas & Liquid Analysis: They provide efficient operation and precise control in analytical instruments.

- Chemical Analysis: Integrated into sophisticated systems, BP7 micropumps facilitate accurate chemical dosing and mixing.

- Lab Testing: Perfect for precise fluid control in analytical equipment.

- Liquid Handling and Dosing: Designed for accurate dosing applications, ensuring minimal contamination.

- Air Quality Monitoring: BP7 micropumps are crucial for sampling and measuring air quality parameters accurately.

Overall, the BP7 micropump’s design and functionality make it a reliable choice for diverse fluid handling tasks across multiple sectors.

Conclusion

The Bartels BP7 piezoelectric micropump offers a cutting-edge solution for precise fluid handling in a wide range of industries. Its small size, energy efficiency, versatility in handling liquids and gases, and minimal maintenance requirements make it a top choice for microfluidic systems.

This blog provided a general overview of the BP7 micropump’s features and benefits. For more in-depth information on specific aspects of the BP7, check out our detailed guides, including topics such as the MP-Multiboard2 and comparison of the different Bartels MP-Drivers, Multiboard2 App Software for BP7 pump control, components of a BP7 microfluidic system, and more on our blog.

To stay updated on any changes, updates, or upgrades to Bartels products, including datasheets and technical specifications, please refer to the Bartels Mikrotechnik download area.

📧 If you have any questions or feedback, please feel free to contact us at support@darwin-microfluidics.com.