Piezoelectric pumps have gained significant attention in various industries, including biomedicine, fuel delivery, liquid cooling, and precision fluid control systems. Due to their compact size, high precision, and efficient energy conversion, these pumps have become an essential component in modern microfluidic systems. This comprehensive guide provides an in-depth understanding of how piezoelectric pumps function, their advantages, and the various configurations available, making them suitable for diverse applications.

What Are Piezoelectric Pumps?

Piezoelectric pumps are a type of displacement pump that utilize the piezoelectric effect—a phenomenon where certain materials generate mechanical strain when an electric voltage is applied. In these pumps, a piezoelectric element, typically a ceramic disk, deforms in response to an electric field. This deformation causes the diaphragm within the pump chamber to move, generating pressure variations that drive fluid movement.

Key Components of a Piezoelectric Pump

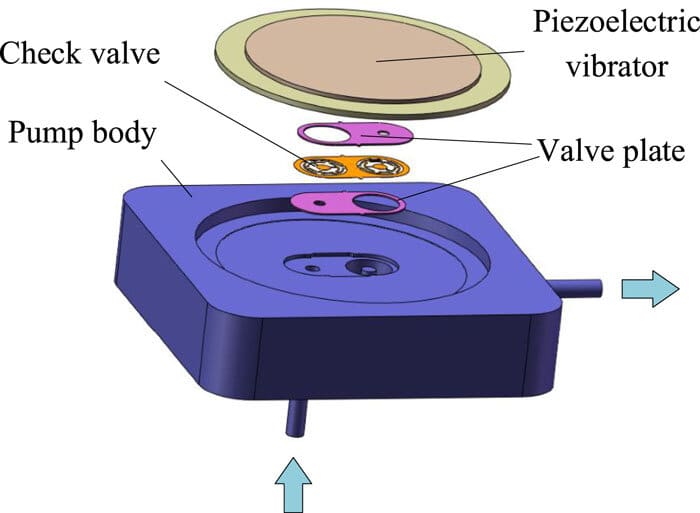

A piezoelectric pump consists of key components such as chambers, valves, and vibrators, all working together to efficiently channel fluids. The system relies on a power source that provides the necessary voltage to deform the piezoelectric material which, when subjected to electric tension, undergoes mechanical deformation. This deformation drives the movement of the working fluid.

Inside the pump, fluid chambers hold the liquid while directional flow is controlled by valves. The mechanical energy generated by the piezoelectric actuator is converted into kinetic energy, enabling precise and controlled fluid flow. This mechanism makes piezoelectric pumps ideal for applications requiring accurate fluid delivery.

Applications of Piezoelectric Pumps

Piezoelectric pumps are widely used across various industries due to their precision, compact design, and efficiency, making them especially suitable for specialized applications.

In biomedicine, they are essential for drug delivery systems, allowing for controlled and precise medication dosing. They also play a crucial role in lab-on-a-chip devices, facilitating the manipulation of tiny fluid volumes for biological and chemical analysis.

In the automotive and energy sectors, piezoelectric pumps are used in fuel injection systems to ensure efficient and accurate fuel delivery. These pumps also contribute to micro-scale energy harvesting systems, helping to transport fluids and improve fuel efficiency.

In electronics, piezoelectric pumps are employed in liquid cooling systems, managing the heat generated by microprocessors and other high-performance components. Additionally, in the field of chemistry and research, these pumps enable precise fluid handling, making them ideal for sensitive experiments and analysis where accuracy is paramount.

How Do Piezoelectric Pumps Work?

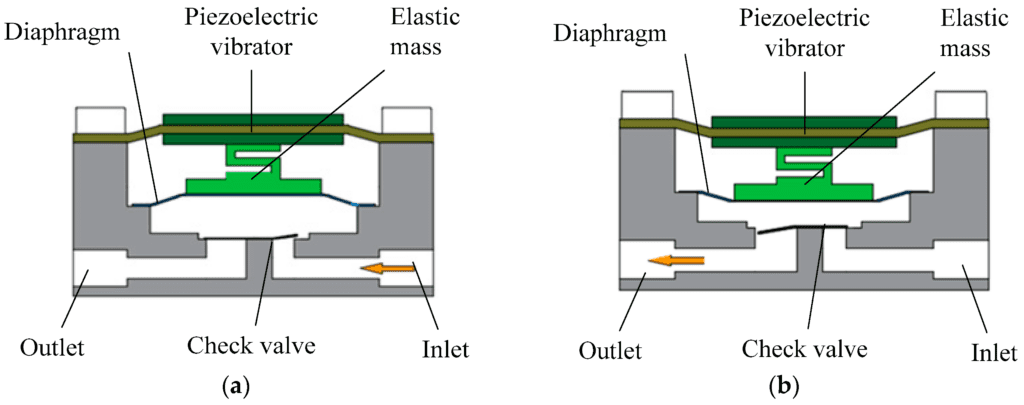

The operation of piezoelectric pumps is based on the inverse piezoelectric effect, where an applied electric field causes a piezoelectric material to deform. This deformation drives a diaphragm within the pump, creating pressure differentials that push fluid through the pump chamber. The process can be summarized as follows:

- Voltage Application: An electric voltage is applied to the piezoelectric element, causing it to deform.

- Diaphragm Movement: The deformation of the piezoelectric element leads to the expansion and contraction of the diaphragm.

- Fluid Movement: The diaphragm’s movement generates pressure differences in the chamber, causing fluid to flow in one direction, regulated by passive check valves.

- Flow Control: The rate of fluid flow is controlled by adjusting the voltage and frequency applied to the piezoelectric element, providing highly precise flow control.

Advantages and Limitations of Piezoelectric Pumps?

Understanding the strengths and limitations of piezoelectric pumps is crucial for selecting the right solution for your needs. This section highlights the key advantages and potential drawbacks to consider, helping you make an informed choice.

✅ Advantages

Piezoelectric pumps offer several benefits that make them a preferred choice for various applications. These include:

- Compact and Lightweight: Their small form factor makes them ideal for integration into space-constrained devices.

- Rapid Dynamic Response: These pumps respond quickly to changes in the applied voltage, enabling precise fluid control.

- High Reliability: With fewer moving parts, piezoelectric pumps have lower wear and tear, leading to greater durability.

- Low Power Consumption: They are highly energy-efficient, making them suitable for portable devices.

- Open Reservoir Compatibility: Similar to peristaltic pumps, piezoelectric pumps can operate with open reservoirs, allowing them to work continuously for extended periods in various fluid handling systems.

❌ Limitations

While piezoelectric pumps offer numerous advantages, they also have some limitations that must be considered:

- Low Back Pressure Tolerance: Piezoelectric pumps are generally limited in handling high back pressures.

- Limited Flow Rates: Piezoelectric pumps are best suited for small volume applications and may not be suitable for higher flow rates.

- Limited Viscosity Range: These pumps perform best with low-viscosity fluids, and their efficiency decreases when handling more viscous substances.

- Pulsatile Flow: While piezoelectric pumps are precise, the flow they generate can be somewhat pulsed, which may require additional damping or smoothing for certain applications.

- Low Chemical Compatibility: Piezoelectric pumps have limited compatibility with organic solvents, which can restrict their use with certain chemicals.

- External Flow Sensor Requirement: These pumps often need to be used with an external flow sensor to ensure accurate monitoring and control.

- Sensitivity to Air Bubbles: Piezoelectric pumps are highly sensitive to air bubbles, which can disrupt fluid flow and reduce efficiency.

Conclusion

Piezoelectric pumps have become an essential component in modern microfluidic and precision fluid control systems. Their compact size, high reliability, and precision make them ideal for a wide range of applications, from medical devices to fuel delivery systems. As research continues, the technology behind piezoelectric pumps is expected to evolve, further enhancing their performance and expanding their application potential in various fields.

Stay tuned for more insights on optimizing piezoelectric pump performance, including working with the Bartels BP7 piezoelectric micropumps and their operating environments, and troubleshooting common operational challenges! Until then, keep your piezoelectric micropumps performing at their best and remember: With the right charge, your micropump will always be in charge! 🚀

📧 If you have any questions or feedback, please feel free to contact us at contact@darwin-microfluidics.com.