This application note uses flow accuracy measurement data from the Ismatec Reglo ICC peristaltic pump to show the impact of different tubing sizes and flow rates on the accuracy of the instrument, and pulsatility of the flow.

Features of the Ismatec Reglo ICC peristaltic pump

The principle of peristaltic pumping is based on the compression and relaxation of flexible tubing. To do this, rotating rollers pass along the tubing inside the pump and compress it to create a vacuum in the tubing, which pulls the fluid in one direction or another. Should you want to learn more on this topic, you can find our A Comprehensive Guide here.

The Reglo ICC peristaltic pump allows independent control of 4 channels from 0.1 to 100 rpm with a resolution of 0.01 rpm. Easy to use, it allows you to create your own program using all the following operations: start, stop, dispense, reverse, aspirate, calibrate.

Only 3-stop tubing is compatible with the Reglo ICC. The pump hand can handle tubing diameters from 0.13 to 3.17 mm ID. For our tests, we used two tubing with inner diameters of 0.25 and 1 mm.

Flow accuracy measurement tests

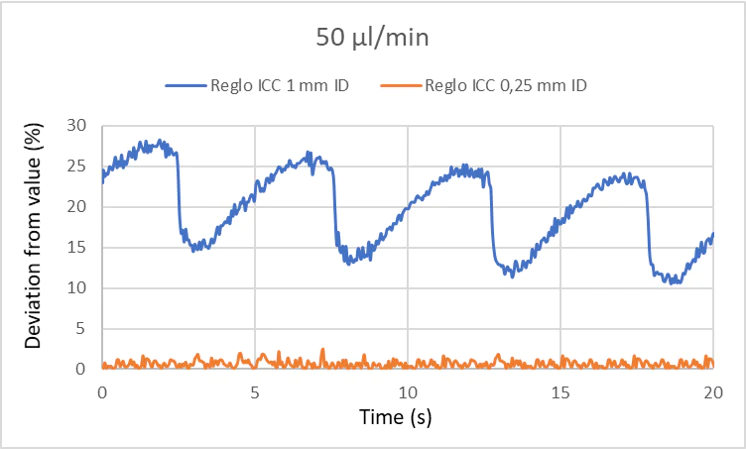

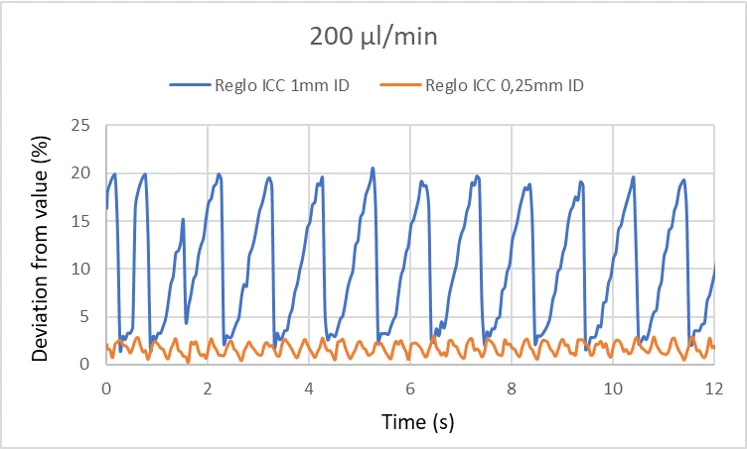

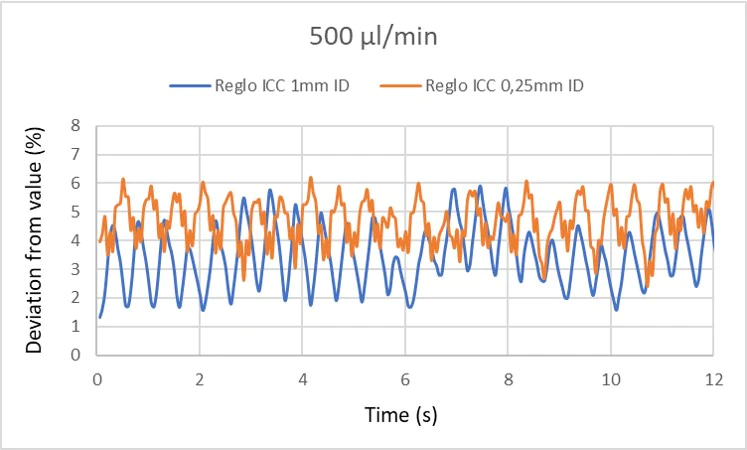

For our tests, we chose to compare the flow rate obtained with two 3-stop tubes of 0.25 and 1 mm ID using the Reglo ICC peristaltic pump. The accuracy is measured using the Elveflow MFS4, and values compared to the set value from 50 to 500 µl/min.

At low (50 µl/min) and intermediate flow rates (200 µl/min), the internal diameter of the tubing has a major influence on the flow measurement.

Indeed, the use of 1mm ID tubing has a deviation profile of about 30%, which can be problematic when used for applications that require real flow accuracy. However, the use of 0.25mm ID tubing is well suited to applications where precision flow is required as the profile shows a deviation from the value close to 0 at 50 µl/min and 2% at 200 µl/min.

For large flows, it appears that the use of large or small diameter tubing has no influence. Indeed, both show an approximately similar profile of deviation from the value of about 5%.

The impact of flow pulsatility on a peristaltic pump flow rate.

Periodic flow pulsatility is inherent to peristaltic pumps, due to the backflow created by the rollers when compressing the tubes. However, this pulsatility can be reduced with the appropriate tubing. This is shown here at 50 and 200 µl/min, where a smaller tubing has a big impact on the flow pulsatility. The tubing diameter should be chosen according to the desired flow range, to get the best combination between flow accuracy and low pulsatility.

The peristaltic pump remains the most suitable pumping system in the case of recirculation or to multiplex experiments at a fairly low cost.

💡Tips to avoid pulsatility in the flow of your peristaltic pump.

• When deciding on a peristaltic pump, remember that more rollers in the head will provide more accuracy at lower flow rates.

• Select tubing size based on desired flow rate; smaller diameters result in steadier performance with low flows!

• In some applications, such as organ-on-chip experiments, some pulsatility is completely acceptable. If unsure, contact us for help to provide you with the best setup for your project 🙂