Connecting your tubing to a syringe pump is usually fairly simple. Every standard syringe has Luer or Luer Lock connection, making it easy to interface it with any type of tubing for your microfluidic experiments.

However, the type of connection differs if you are using a soft-walled tubing (silicone, Tygon…) or rigid tubing (PTFE, PEEK…). Let’s see how to connect your syringe pump to your microfluidic setup with this tutorial!

Soft-walled (silicone, Tygon…) tubing

The advantage of the soft-walled tubing is its versatility when interfacing it with your microfluidic system. The deformation of the microfluidic tubing can be used for leak-free connections in various ways:

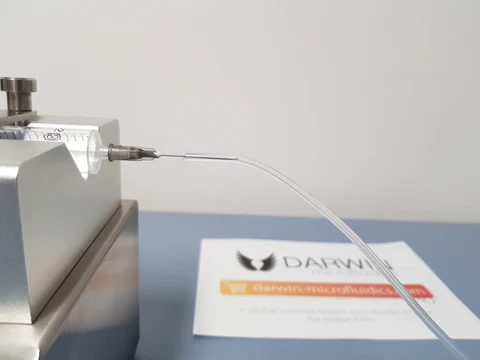

Connect a syringe pump to a soft-walled tubing using a needle

Just plug a needle of your choice on the Luer end of the syringe (conversion table between gauge sizes and inner / outer diameter).

Then, just insert your tubing on the needle. That’s it!

💡Tip: Always choose a needle with a larger outer diameter than the inner diameter of your tubing to avoid leakages.

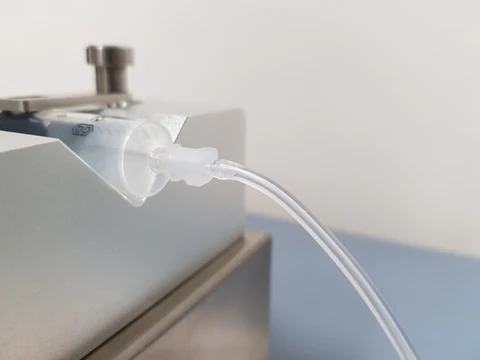

Connect a syringe pump to soft-walled tubing using an adapter

This is another way to connect your tubing easily: just plug a Female Luer to Barbed fitting on the syringe (works for both Luer and Luer Lock end syringes), and connect the silicone tubing to it. This adapter is available for 1/16″ ID, 1/8″ ID and 3/32″ ID tubing.

If you are working with other tubing sizes, just take the fitting size above the inner diameter (ID) of your tubing! For example, if you are working with a 1/32″ ID soft-walled tubing, use the connector for 1/16″ ID tube.

Rigid (PTFE, PEEK…) tubing

Rigid tubing is more reliable than soft-walled one for microfluidic experiments, since it can be connected with leak-proof fittings using ferrules to minimise the internal volume. However, rigid tubing should not be used with needles or barbed connectors as no deformation of the tubing wall will occur, and an interface must be created.

As a standard for rigid tubing, we will take 1/4″-28 fittings and ferrules for 1/16″ outer diameter (OD) tubing.

First, let’s interface the Luer end of the syringe with 1/4″-28 connectors using these Female Luer to Female 1/4″-28 adapters.

Then, connect your tubing to this adapter using standard 1/4″-28 connectors to 1/16″ OD tubing.

You now have a leak-free interface to work with your syringe pump!