Definition of Soft Lithography

Soft lithography refers to a family of techniques for fabricating or replicating structures using “soft” materials, typically elastomers. It is a popular choice for creating microfluidic devices due to its relative simplicity, low cost, and versatility. It allows for the creation of complex, three-dimensional structures with high precision, which is essential in microfluidics.

Understanding Soft Lithography

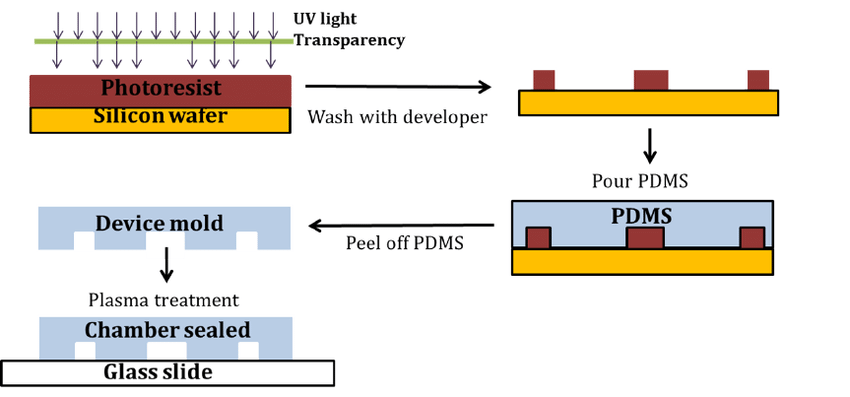

The soft lithography process typically begins with photolithography, where a pattern is transferred from a photomask to a light-sensitive material (photoresist) on a substrate. This patterned photoresist serves as a mold or master for replication using an elastomer, most commonly polydimethylsiloxane (PDMS). The PDMS is poured over the master, cured, and then peeled off, resulting in a precise replica of the original pattern. This replication process is known as replica molding or REM, one of the techniques of soft lithography.

Soft lithography allows for the creation of structures on both flat and curved surfaces, in both two and three dimensions. This adaptability is particularly valuable in microfluidics, where manipulating fluids in three-dimensional spaces is often required.

Techniques of Soft Lithography

There are several techniques of soft lithography, each suited to specific applications:

- Replica Molding (REM): The most straightforward and widely used technique, ideal for creating simple microfluidic channels.

- Microtransfer Molding (μTM): Involves transferring a pattern from a master to a substrate using an elastomer stamp, facilitating the creation of multilevel structures.

- Micromolding in Capillaries (MIMIC): Utilizes capillaries filled with liquid pre-polymer that is cured to form large-area patterns.

- Solvent-Assisted Micromolding (SAMIM): Involves using a solvent to swell the elastomer and transfer a pattern, allowing for the creation of nanostructures.

- Multilayer Soft Lithography (MSL): Stacks and bonds multiple PDMS layers to construct complex, three-dimensional microfluidic devices.

Applications in Microfluidics

Soft lithography is widely used in microfluidics to create devices ranging from simple fluidic channels to sophisticated three-dimensional systems for chemical analysis, biological assays, and more. Its ability to produce microscale structures with high precision is crucial for manipulating fluids in ways that were previously challenging.

Other applications include microreactors for chemical synthesis, microscale heat exchangers for thermal management, and microscale fuel cells for energy production.

Advantages and Limitations of Soft Lithography

Soft lithography offers several advantages over traditional lithographic techniques. It is relatively simple and inexpensive, requiring less specialized equipment and materials. It is also highly versatile, capable of creating structures on both flat and curved surfaces, and in both two and three dimensions making it ideal for a wide range of applications in microfluidics.

However, soft lithography has its limitations. The resolution of the structures depends on the quality of the master and the properties of the elastomer. While nanoscale structures can be created, achieving such fine detail is challenging and requires specialized techniques. Additionally, while PDMS is widely used due to its favorable properties, it is not suitable for all applications, particularly those involving exposure to gases and non-polar solvents, to which PDMS is permeable.

Overcoming Limitations

Researchers are actively developing new techniques and materials to address the limitations of soft lithography. For instance, advances in photoresists and elastomers are enhancing resolution and expanding the range of materials that can be used. Additionally, techniques such as nanoimprint lithography and two-photon polymerization are being explored for nanoscale fabrication.

Other innovations include backside exposure and double casting, which allow for more complex, three-dimensional structures. Backside exposure involves exposing the photoresist through the backside of the substrate, enabling the creation of structures with non-vertical sidewalls while double casting involves using a secondary master to create structures with intricate geometries.

Conclusion

Soft lithography has revolutionized microfluidics by enabling the fabrication of microscale structures with precision and versatility. From simple fluidic channels to advanced three-dimensional devices, soft lithography has opened new possibilities in chemical analysis, biological assays, and beyond. With continuous innovation, the role of soft lithography in microfluidics is set to expand, allowing for new applications and breakthroughs in science and technology.