Definition of Photopolymerization

Photopolymerization is a process that involves the use of light to initiate a chemical reaction that results in the formation of polymers. This process is extensively used in various fields, including the field of microfluidics where photopolymerization creates microstructures with high precision essential for the functioning of microfluidic devices.

Understanding Photopolymerization

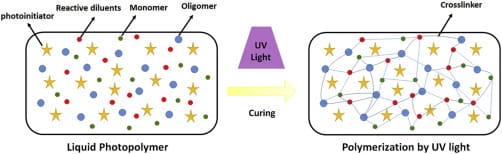

Photopolymerization is a type of polymerization that uses light to trigger a chemical reaction that forms polymers. Polymers are large molecules made up of repeating subunits, known as monomers. When exposed to light, particularly in the ultraviolet or visible spectrum, photosensitive monomers or oligomers become excited and form bonds with each other, creating polymers. This process can be precisely controlled, making it ideal for creating complex microstructures.

The type and properties of the polymer formed depend on the type of monomer or oligomer used and the conditions of the reaction.

Types of Photopolymerization

There are two main types of photopolymerization: free radical and cationic. Free radical photopolymerization is initiated by photoinitiators that absorb light and produce free radicals, which then trigger polymer formation. Cationic photopolymerization, on the other hand, is initiated by photoinitiators that absorb light and produce positive ions, or cations that react with monomers to form polymers.

Free radical photopolymerization is fast and can be used with a wide range of monomers, but can be inhibited by oxygen and may not be suitable for some applications. Cationic photopolymerization is slower but more oxygen-resistant.

Applications of Photopolymerization

Photopolymerization has a wide range of applications across industries, as it is used to create coatings that are resistant to chemicals, abrasion, and UV light and to create adhesives that can bond materials quickly and securely. Additionally, it is used for the fabrication of microstructures with high precision for microfluidic devices.

Photopolymerization in Microfluidics

As mentioned, photopolymerization allows the creation of microstructures. These can be used to control the flow of fluids in microfluidic devices, enabling the manipulation of fluids at the microscale which is essential for many applications in chemistry, biology, and medicine.

The use of photopolymerization in microfluidics involves the use of a photosensitive material, such as a photopolymer or a photoresist, which is exposed to light through a mask that defines the pattern of the microstructures to be created. The exposed areas undergo a chemical reaction to form polymers, while the unexposed areas are removed, leaving behind the desired structures.

Materials Used in Photopolymerization

The choice of material for photopolymerization in microfluidics depends on the application. For applications that require high chemical resistance, photopolymers , which polymerize under light, offer such properties alongside optical clarity.. For applications needing high resolution, photoresists are preferred, as they change solubility when exposed to light, enabling precise microstructure creation.

Other factors can influence the choice of material including the wavelength of the light used, the desired properties of the polymer and the compatibility of the material with other components of the microfluidic device. Thus, selecting the appropriate material is crucial for microfluidic device design and fabrication.

Techniques Used in Photopolymerization

Several techniques are used for photopolymerization in microfluidics, including photolithography, stereolithography, and two-photon polymerization.

- Photolithography uses light to transfer a pattern from a mask to a photosensitive material, widely used in the fabrication of microfluidic devices due to its high resolution and compatibility with a wide range of materials.

- Stereolithography uses a laser to polymerize a photosensitive material layer by layer, allowing for the fabrication of three-dimensional microstructures.

- Two-photon polymerization initiates polymerization of a photosensitive material using two photons, enabling the creation of high-resolution three-dimensional structures.

Each technique has its advantages and limitations, with the choice depending on the application’s specific needs, such as resolution, material compatibility, and structural complexity.

Challenges and Future Directions

Despite the many advantages of using photopolymerization in microfluidics, there are several challenges that need to be addressed. The primary challenge is the control of the polymerization process to achieve the desired material properties of the polymer, such as its mechanical strength and chemical resistance.

Another challenge is the integration of the microfluidic device with other components, such as sensors and actuators. Moreover, there is a need for the development of techniques for a mass production of microfluidic devices, as current fabrication techniques are often time-consuming and expensive.

Future research is expected to focus on developing new materials with enhanced properties, such as greater mechanical strength and chemical resistance, and on refining photopolymerization techniques to offer higher resolution and faster fabrication times. These advancements will likely expand the capabilities and applications of microfluidic devices in various fields.

Conclusion

Photopolymerization is an important technique in microfluidics, allowing for the precise fabrication of intricate microstructures. While there are challenges in material selection and process control, continuous advancements are enhancing its effectiveness, opening up the way for innovative microfluidic device designs and applications.