Tubing is an essential element in the design of your microfluidic platform, being the link between the different components of this platform. As it is in contact with the fluids, the choice of tubing is mainly determined by the chemical compatibility with the fluids you use, but also by other parameters (pressure in the system, compatibility with the elements in your setup, etc.).

Given the large number of materials used, it is easy to get lost. In this guide, we compare the different types of fluoropolymers available on the market and their physico-chemical properties.

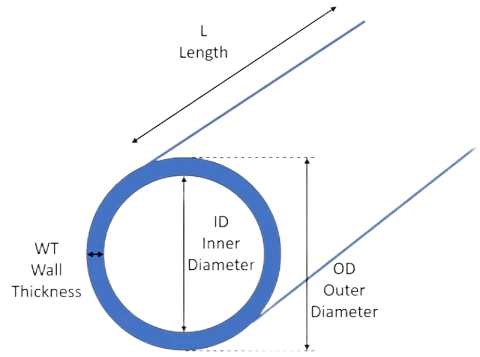

Dimensions

Let’s first take a look at some of the dimensions and main abbreviations, which will be useful to define your needs.

Fluoropolymer tubing for microfluidics

PTFE (PolyTetraFluoroEthylene, often described as Teflon®)

PTFE tubing has the best performances in terms of chemical and thermal resistance and non-stick properties. Compared to similar fluoropolymers, PTFE offers the best price/performance ratio. In fact, it has many advantages, including unrivaled chemical resistance, a surface that facilitates flow, non-toxicity and chemical inert properties. When used in microfluidics, its rigidity can stabilize the flow rate and increase the reactivity of your microfluidic system.

PTFE can operate from -190°C to 260°C, and has a very low water absorption rate (< 0.01%).

FEP (Fluorinated Ethylene-Propylene)

This attractive alternative to PTFE tubes has many similar properties such as biocompatibility and remarkable inertness to most chemicals. FEP is the preferred material in production of small diameter tubing of continuous lengths. Like PTFE, this flexible material is mainly used for low-pressure microfluidic applications. In addition, thanks to its excellent clarity, it is ideal for sight glass/flow monitoring applications. FEP tubing also has better gas and vapor permeability properties and excellent UV transmission ratings.

FEP tubing can operate between -190°C and 205°C, has a slightly higher coefficient of friction, and is more transparent than PTFE.

FEP (Fluorinated Ethylene-Propylene)

This attractive alternative to PTFE tubes has many similar properties such as biocompatibility and remarkable inertness to most chemicals. FEP is the preferred material in production of small diameter tubing of continuous lengths. Like PTFE, this flexible material is mainly used for low-pressure microfluidic applications. In addition, thanks to its excellent clarity, it is ideal for sight glass/flow monitoring applications. FEP tubing also has better gas and vapor permeability properties and excellent UV transmission ratings.

FEP tubing can operate between -190°C and 205°C, has a slightly higher coefficient of friction, and is more transparent than PTFE.

PEEK (Poly Ether Ether Ketone)

PEEK is often considered as one of the most performant polymers, and is commonly used in microfluidics for its reliability and resistance to pressure. It combines high mechanical and chemical resistance properties, together with a working temperature range from -40°C to 250°C. PEEK tubing has one of the highest strength-to-weight ratios of all thermoplastics and can be used in numerous low and high pressure applications. It is inert to most solvents and has a smooth internal surface that increases the swept volume.

PFA (PerFluoroAlkoxy)

PFA tubing is the right choice when high optical clarity, flexibility and high continuous working temperatures are required. It combines the properties of FEP and PTFE, with working temperatures to -200°C to 260°C. PFA has a lower melting temperature than PTFE, is UV resistant, and has a very low water absorption rate (< 0.01%).

ETFE (Ethylene TetraFluoroEthylene)

ETFE is chemically inert and offers very good resistance to solvents. It has a stiffer structure than PTFE, FEP and PFA, which makes the tube more resistant to collapse. Also, this material offers greater durability and is less permeable to gases than other types of tubing. Its operating temperature ranges from -200°C to 150°C.

Tubing and connectors

As explained in details here (Internal volume, swept volume, dead volume in microfluidics), it is important to choose connectors that reduce the internal volume as much as possible. Darwin Microfluidics offers a selection of tubing and connectors with low internal volume, which can be found in our Tubing and Fittings & Connectors sections.