The objective of microfluidics is to miniaturize as much as possible all the components of the microfluidic platform, which implies the use and manipulation of very low volumes (named internal volume) ranging from ten nanolitres to a hundred microlitres.

Needless to say that the handling of liquid through different components cannot be done without a slight loss of volume (called dead volume). Nowadays, the challenge is to design the chips and elements with the lowest dead volume possible.

In this review, we will define the different volumes encountered in microfluidics and how to reduce them.

Volumes in microfluidics

Internal volume

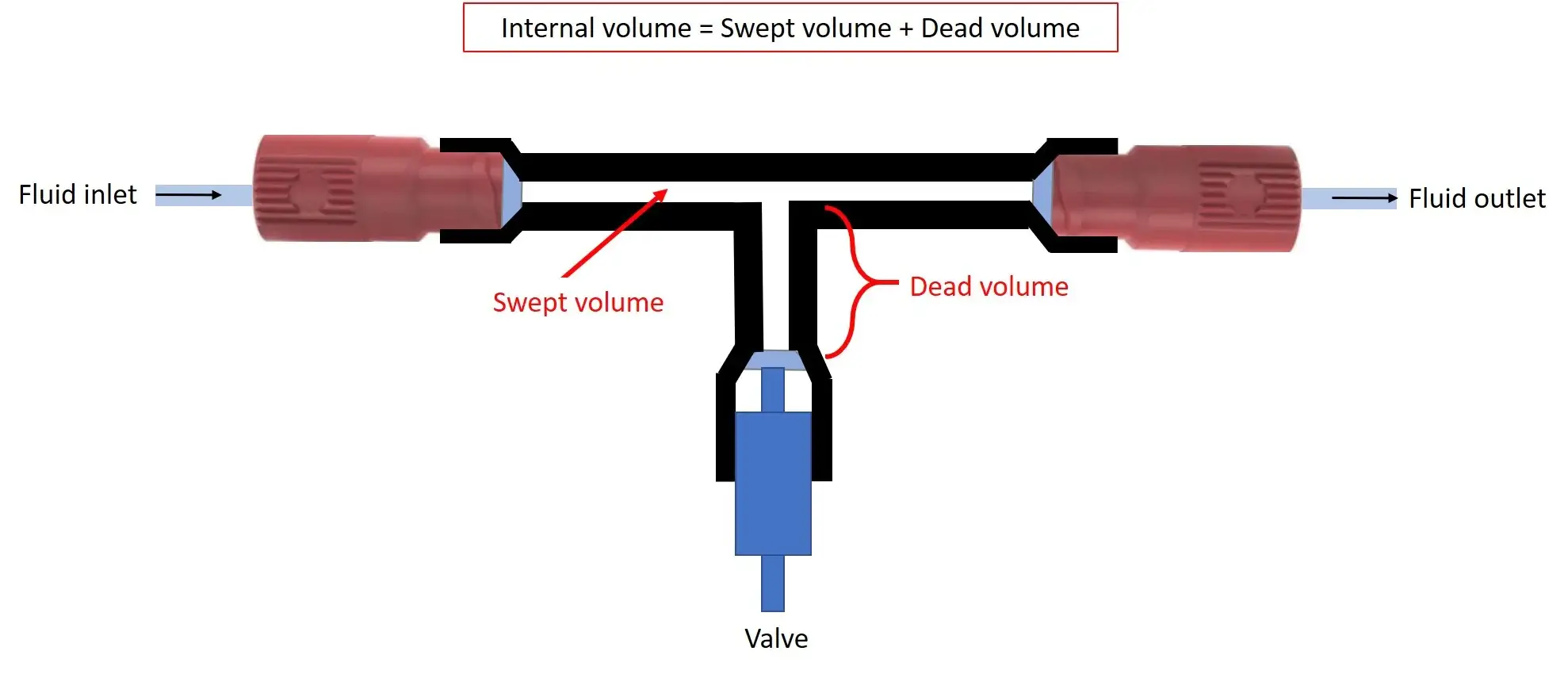

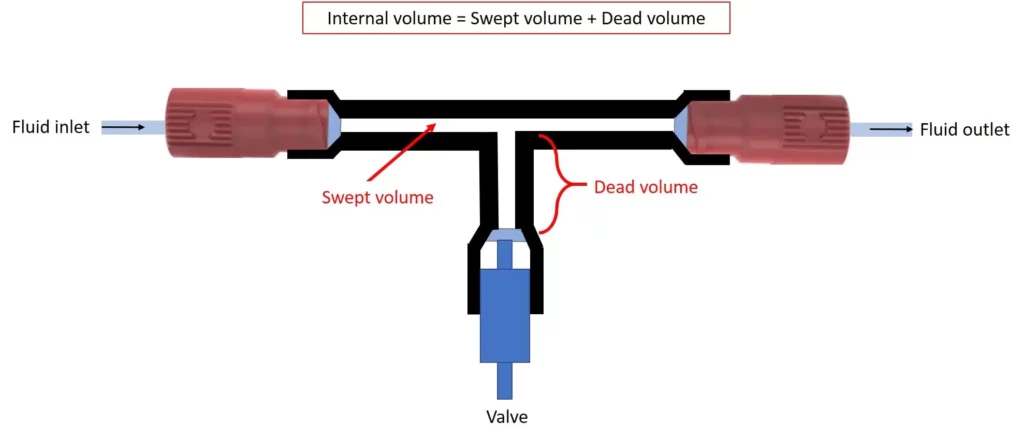

Generally speaking, the internal volume is defined as the sum of the dead volume and the volume swept by the flow within a component or system.

Dead volume

The dead volume is the part of the internal volume that does not belong to the flow path. This means this part of the liquid, once the flow has been diffused, cannot be recovered, or may be recovered later. As mentioned in the introduction, the challenge for manufacturers of microfluidic parts is to minimise dead volumes in their products. Indeed, this can be a problem when several samples have to pass through the same path but must not contaminate each other.

Swept volume

The swept volume is the part of the internal volume that is directly in the flow path: fluids must pass through this volume when flowing through the fitting. As the other types of volume mentioned above, it is preferable to have this swept volume as low as possible.

How to reduce volumes in microfluidics ?

Each component of a microfluidic system (tube, connector, channel, valves) has an internal volume. Generally, there is a tendency to want the dead volume and the swept volume as low as possible. This is particularly critical when working with samples that are available in very limited quantities.

We suggest that you take a look at some tips that can help reduce these volumes.

In order to minimise the internal volume of a microfluidic system, it is logical to think – without referring to laborious mathematical equations – of the volume associated with the channels of the microfluidic chip. We are therefore going to rush to a new, fairly efficient chip design that will enable these volumes to be reduced. However, more often, you will find that most of the internal volumes are not associated with the microfluidic channels, but rather with other elements such as connectors, tubing, valves or pumps.

How Darwin Microfluidics can help you?

The key is to rely on elements (beyond the design of the chip) created specifically for microfluidics, but above all, which considerably reduce the internal volume. Darwin Microfluidics offers a full catalog of fittings & connectors, along with tubing to meet the most demanding applications.

Get in touch with our team, we’ll be happy to assist you!