To conduct basic tests with Bartels micropumps, the Bartels basic set provides an ideal starting point, including the essential components needed for initial trials. However, for more advanced studies or comprehensive microfluidic applications, the Bartels advance evaluation set is required. This set extends beyond the capabilities of the basic set by incorporating additional critical components such as a microfluidic chip, pressure and flow sensors, valves, valve drivers, dampers, connectors, and connection cables.

In this blog post, we will explore the essential components of the Bartels advance set and how they enable users to perform precise control and analysis of microfluidic systems, offering deeper insights and functionality beyond basic testing. Each component plays a vital role in enhancing performance, expanding the range of possible experiments with the BP7 micropumps, and improving system integration.

Mp-Basic Evaluation Set

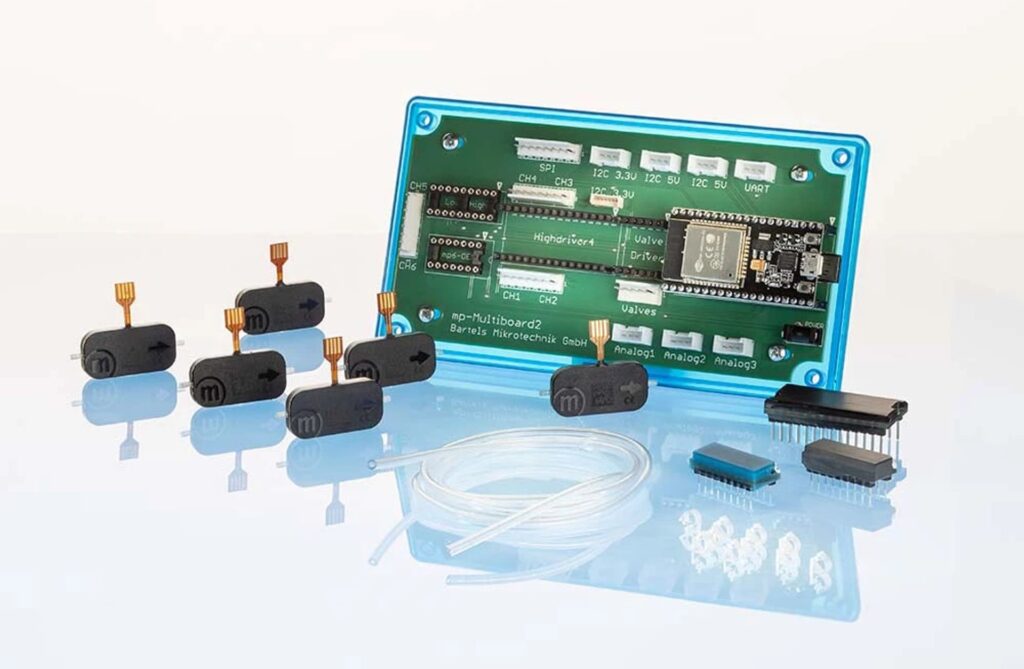

Before diving into the advanced components of Bartels’ micropump systems, it’s important to briefly acknowledge the mp-basic evaluation set, which provides the foundation for testing Bartels micropumps. This set includes the mp-Multiboard2 controller, which operates via a simple software interface and is equipped with four drivers—Lowdriver, Driver, Highdriver, and Highdriver4—to support a range of flow rates. The kit also comes with 6 BP7 Tubing micropumps, one meter of 1.3 mm ID Tygon LMT-55 tubing, and mp-hc hose clamps to ensure secure, leak-proof connections between the pump and tubing.

The mp-hc hose clamps, designed for Bartels micropumps, prevent unwanted disconnection or leakages. With an inner diameter of 3 mm and dimensions of 4 x 5.1 mm, these clamps ensure a tight fit, contributing to the system’s reliability.

Additionally, the Tygon LMT-55 tubing, with a 1.3 mm inner diameter and 3 mm outer diameter, is transparent, autoclavable, and EtO-sterilizable, making it ideal for various fluid handling applications. For more details on the chemical resistance properties of Tygon LMT-55, be sure to check our comprehensive user guide.

For a complete breakdown of the basic set and its components, specifically the mp-Multiboard2 and the different micropump drivers, you can refer to our detailed blog post entitled: Bartels Mp-Multiboard2 and Comparison of the Mp-Drivers.

Mp-Advance Evaluation Set

The mp-advance evaluation set builds on the basic set by adding extra components for more in-depth testing and complex microfluidic setups.

Along with the essentials, the advance set includes key additions like flow and pressure sensors, valves with drivers, a microfluidic chip, and dampers. These components give users more control and flexibility when working with Bartels micropumps, allowing for greater precision in experiments.

Mp-ValvedriverT and Takasago Valves

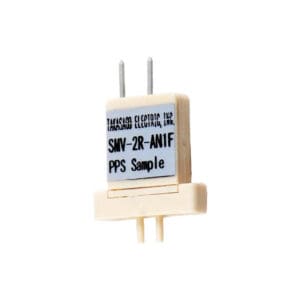

The mp-valvedriverT is an essential driver for precisely controlling up to two Takasago SMV valves through the Multiboard2, ensuring efficient fluid management. Compact in size, with dimensions of 16 x 40 x 1.6 mm, the mp-valvedriverT operates with a power supply range of 4.5 to 17 VDC and consumes approximately 0.85 mA at 5 V.

The Takasago SMV 2/2 NC Active Valve is a shape-memory alloy valve that integrates with the Multiboard2, using the mp-valvedriverT. This 2/2 normally closed valve is nearly silent, it has a compact design, with dimensions of 4.0 x 18.4 x 19 mm, and durable materials—PPS for the valve body and FPM for the membrane. With a power consumption of just 0.3 W and a switching time of 600 ms, it provides efficient fluid control within the system.

SLF3S-0600F Flow Sensor

The SLF3S-0600F sensor, from Sensirion, is integrated with the Bartels Multiboard2, enabling straightforward monitoring of flow rates in microfluidic applications. The sensor supports flow ranges of 0-2000 µL/min and offers an accuracy and a repeatability, for water, of ±5% of the measured value (or 0.5 µL/min, whichever is larger), ensuring reliable measurements even at low flow rates.

Honeywell ABP Pressure Sensor

The Honeywell ABP pressure sensor is a high-precision, digital sensor designed for use with the Bartels Multiboard2, making it easy to monitor pressure in microfluidic systems. It covers a pressure range from 0 to 1 bar (0 to 15 psi), with a remarkable accuracy of ±0.25% and a long-term stability, ensuring precise measurements. Compatible with dry gases and non-corrosive fluids, it connects to the Multiboard2 via the provided 4-pin Grove connector cable. Ideal for experiments requiring sensitive pressure control.

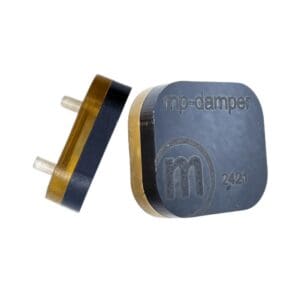

Mp-Damper

The mp-damper is specifically designed to minimize pulsations in the flow generated by the BP7 micropumps, helping to achieve a smoother and more consistent flow rate. This is especially beneficial when paired with a flow sensor, ensuring more precise readings. The damper is compact, with dimensions of 17 x 19 x 5 mm, and is constructed from durable materials including PPSU, FKM, PP, and epoxy-based adhesive, making it a reliable solution for reducing flow pulsatility in demanding applications.

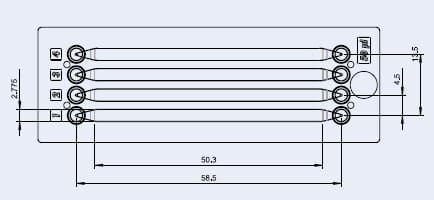

Straight Channel Chip and Mini Luer Connectors

The Straight Channel Chip Fluidic 560 from ChipShop features a channel orientation that runs lengthwise. It includes four channels with a total channel volume of 50 µL. The channels are 2.775 µm wide, 350 µm deep, and 58.5 mm long. The chip’s fluidic interface uses Mini Luer connections, and it is available in different materials such as TOPAS, PC Zeonor, or PS, making it suitable for various microfluidic and chemical compatibility requirements.

With these advanced tools, combined with the easy-to-use mp-Multiboard2, this set offers an advanced look at Bartels’ product lineup and opens the door to more detailed testing and system optimization.

Conclusion

The Bartels advance set offers a comprehensive and versatile solution for those aiming to go beyond basic micropump testing. With added components such as sensors, valves, and more, it allows for precise control, detailed analysis, and smooth integration of complex microfluidic systems. Whether you’re working with advanced flow regulation, pressure management, or complex fluidic circuits, the advance set is designed to meet the demands of microfluidic research and applications.

For a more detailed overview of the BP7 micropump, its full range of features, and system components, check out our Bartels BP7 overview blog. You’ll also find other helpful guides in this blog series, including detailed posts on topics like instructions and tips for appropriate handling of the BP7 micropumps and the chemical compatibility of PPSU, which is the body material of BP7 micropumps.

To stay updated on any changes or upgrades to Bartels products, including datasheets and technical specifications, please refer to the Bartels Mikrotechnik download area.

📧 If you have any questions or feedback, please feel free to contact us at support@darwin-microfluidics.com.