Why Cleaning Matters in Microfluidics?

Microfluidic chips are used in delicate and complex processes, such as liposome formation, bioanalysis, and chemical synthesis. Without proper cleaning, even minor contamination can lead to blockages, clogging, or interference with experiments, ultimately compromising the results. Thorough cleaning is crucial for maintaining the longevity and performance of microfluidic chips, preventing costly replacements, and ensuring accurate data.

General Cleaning Guidelines

Proper cleaning is crucial, regardless of the chip material. Inconsistent cleaning practices can lead to contamination, blockages, and even permanent damage to the chip. Before diving into material-specific protocols, here are some general tips that apply to most microfluidic devices to help you maintain them in peak condition:

- Flush Channels After Each Use 🚿: Immediately after use, flush the chip’s channels with a warm water and mild soap solution. This helps to remove any residues or contaminants. Afterward, rinse thoroughly with demineralized (DEMI) water to ensure the channels are clean and free of soap. For more stubborn residues, a gentle cleaning solution can be used, followed by a rinse with water.

- Handle with Care 💎: Microfluidic chips are delicate, and their intricate structures require gentle handling. Avoid using abrasive cleaning methods like scrubbing or scraping, as these can damage the chip’s surface and compromise its functionality.

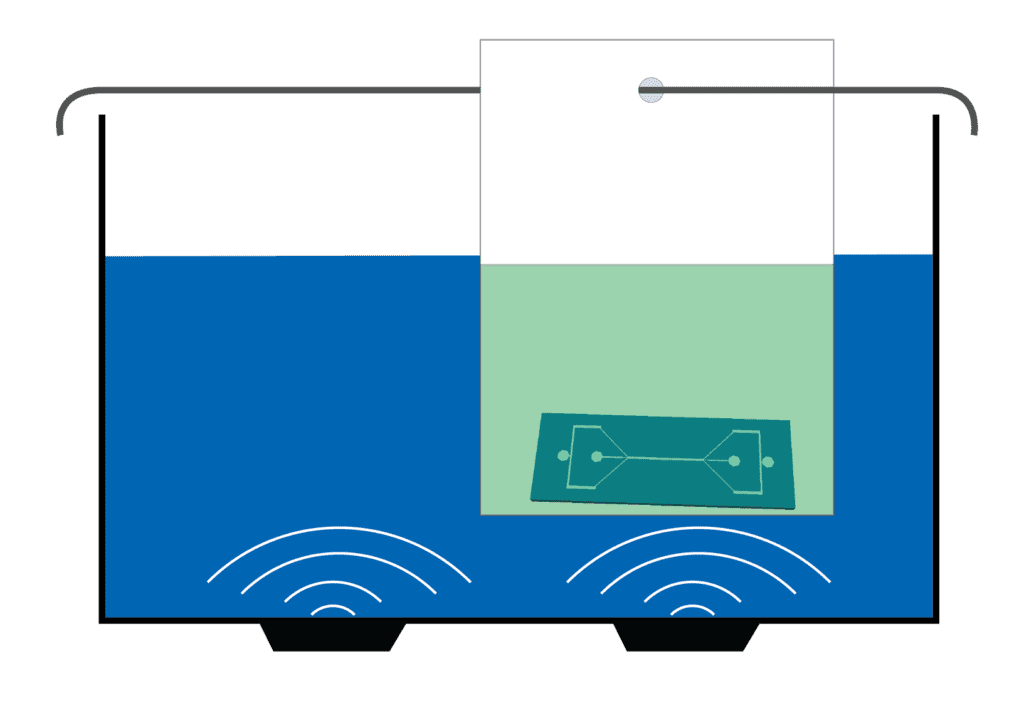

- Use Ultrasonics 🌊: For stubborn residues or particles that cannot be easily removed, an ultrasonic bath is highly effective. Ultrasonic waves create vibrations that help dislodge particles without the need for harsh scrubbing, reducing the risk of damage to the chip. Be sure to select an appropriate cleaning solution for the bath based on the material of the chip.

- Chemical Compatibility 🧪: Always ensure that the cleaning solvents you use are compatible with the chip material. Using a solvent that’s too harsh can lead to degradation, discoloration, or structural damage. Refer to our chemical compatibility charts to make informed choices about your material and prevent any adverse reactions.

- Filter Fluids to Prevent Blockages ⚗️: Filter fluids before introducing them into the chip to minimize the risk of particulates causing blockages or clogging the channels.

- Store Chips in Clean Environments 🌟: Protect your chips from contamination by storing them in sealed containers or dedicated microenvironments with HEPA-filtered air.

Cleaning Glass Microfluidic Chips

Glass chips are robust and highly resistant to chemical and thermal treatments, making them easier to clean in challenging scenarios.

Basic Protocol

When cleaning glass microfluidic chips, start by flushing the channels with isopropyl alcohol (IPA) or ethanol to effectively remove contaminants. Afterward, rinse the chip thoroughly with demineralized (DEMI) water to ensure that no residues remain. Once cleaned, allow the chip to air dry completely before reusing it.

For Biofouling or Organic Residues

For glass chips that have biofouling or organic residues, a more intensive cleaning method is required. Start with ethanol and DEMI water to remove general contaminants, then follow up with concentrated sulfuric acid to dissolve stubborn organic material like fibers or biofilms.

Afterward, rinse thoroughly with distilled water to remove any traces of the acid, and allow the chip to dry completely before reuse.

For Stubborn Blockages

For stubborn blockages in glass chips, sonication is an effective method. Place the chip in an ultrasonic bath filled with ethanol or DEMI water, and allow it to run for several minutes. The ultrasonic vibrations help dislodge particles stuck in the channels without damaging the chip’s structure.

If the blockage persists after sonication, try backflushing by reversing the flow through the channels. This technique can push out any remaining debris, ensuring the channels are fully cleared.

💡 Quick Cleaning Summary for Glass Chips

- Routine Cleaning: Flush with ethanol or IPA, rinse with DEMI water, and air dry.

- For Organic Residues: Use ethanol and DEMI water first, followed by concentrated sulfuric acid. Rinse thoroughly with distilled water.

- For Blockages: Sonicate in ethanol or DEMI water, and backflush if necessary.

Cleaning PDMS Microfluidic Chips

PDMS (Polydimethylsiloxane) chips are versatile. However, cleaning these chips requires special care due to their chemical sensitivity and hydrophobic nature, which can make removing lipids or oils particularly challenging.

Basic Protocol

When cleaning PDMS microfluidic chips, start by flushing the channels with warm water and mild soap solution to remove any residues, followed by a rinse with demineralized (DEMI) water to ensure the surfaces are free of lingering contaminants. After cleaning, let the chip air dry completely before reuse.

It’s important to note that PDMS can swell or degrade when exposed to strong solvents such as acetone or toluene, so these should be avoided to maintain the chip’s integrity. For detailed information on PDMS chemical resistance, refer to the resistance chart for PDMS chips.

For Lipid or Polymerized Residues

For residues like lipids or polymers that may have solidified inside the channels, use the same solvent that was used to dissolve the material during your process—for example, acetonitrile for lipids. Adding ultrasonic cleaning can further aid in dislodging these stubborn residues. Place the chip in an ultrasonic bath filled with warm water for a gentle yet effective cleaning process.

To prevent contamination and maintain performance, always use clean fluids during operation and store PDMS chips in a particle-free environment.

💡 Quick Cleaning Summary for PDMS Chips

- Routine Cleaning: Flush with warm water and mild soap solution, rinse with DEMI water, and air dry.

- For Lipid/Polymer Residues: Use process-specific solvents like acetonitrile and ultrasonic cleaning in water.

Cleaning Thermoplastic Microfluidic Chips

Polymer chips are diverse, including materials like polycarbonate and cyclic olefin copolymer (COC). Cleaning these chips requires extra care due to their susceptibility to damage from harsh chemicals and high temperatures.

Basic Protocol

The basic protocol consists of flushing the channels with a warm water and mild soap solution to clear residues, then rinse thoroughly with demineralized (DEMI) water to ensure all cleaning agents are removed.

If using ultrasonic cleaning, opt for higher-frequency ultrasonic baths, which are gentler on the delicate structures of polymer chips.

For Coating Residues

For chips with coating residues, a mild detergent solution, such as Tween 20, is an effective choice. Rinse with DEMI water after cleaning to remove any detergent traces.

Caution should be exercised when using strong acids or bases, as these can damage the chip material.

For Organic Deposits

For organic deposits, solvents like ethanol or hexane can be used cautiously, ensuring compatibility with the polymer material. Strong solvents, such as acetone, should generally be avoided unless absolutely necessary, as they can degrade or warp the chip. After cleaning with solvents, rinse thoroughly with demineralized (DEMI) water to remove any lingering residuals, and allow the chip to air dry completely before reuse.

💡 Quick Cleaning Summary for Thermoplastic Chips

- Routine Cleaning: Flush with warm water and mild soap solution, rinse with DEMI water, and air dry. Use high-frequency ultrasonics for gentle cleaning.

- For Coating Residues: Clean with Tween 20, rinse with DEMI water, and avoid strong acids/bases.

- For Organic Deposits: Use ethanol/hexane carefully, avoid acetone, rinse with DEMI water, and air dry.

Conclusion

The table below provides a concise summary of some effective cleaning protocols for different chip materials, including PDMS, glass, and various polymers. Each protocol addresses specific applications, considering the chemical compatibility of the materials involved.

Depending on the chip type, ethanol may be substituted with isopropanol to ensure optimal cleaning and material safety. Use this guide to quickly identify the best practices for maintaining and reusing your microfluidic chips.

| Chip Material | Biofouling | Oil Residues | Coating | Cleaning Protocol |

|---|---|---|---|---|

| Glass-PDMS-Polymer | NO | NO | NO | Distilled water / Ethanol 70% / Distilled water |

| Glass-PDMS-Polymer | YES | NO | NO | Distilled water / Ethanol 70% / Distilled water/ Ultrasonic bath |

| Glass-Polymer | YES | YES | NO | Distilled water / Ethanol 70% / Distilled water / SDS 10% / Distilled water |

| PDMS-Polymer | NO | NO | YES | Distilled water / Tween 20 / Distilled water |

| PDMS-Polymer | YES | YES | YES | Do not reuse |

Proper maintenance is key to ensuring the long-term usability of microfluidic chips. Whether your chip is made of glass, PDMS, or a polymer (PC, PS, PMMA, COC, COP, etc.), choosing the right cleaning protocol will save you time, money, and frustration.

By following these detailed guidelines, you can ensure your microfluidic devices remain in a better condition, ready to perform at their best for your next experiment or application.

Stay tuned for more insights into advanced cleaning methods and their role in maintaining microfluidic precision 🧼🚿!

📧 If you have any questions or feedback, please feel free to contact us at contact@darwin-microfluidics.com.

10 Tips For Easy Droplet Generation: A Guide

[…] For more details about how to clean your microfluidic chip, check our blog post: How to clean a microfluidic chip? […]