Droplet generation is a cornerstone in various scientific and industrial applications including but not restricted to: emulsion production, generation of bubbles or foams, drug delivery, nanoparticles synthesis and cell encapsulation. Therefore, droplet generation demands meticulous attention to detail and precision engineering as there are many variables that can affect the size, frequency and consistency of the droplets produced.

In this guide, we present ten essential tips for achieving easy droplet generation. We’ll cover simple yet vital factors such as cleanliness, understanding the surfaces you’re working with, and controlling the environment around you to optimize your droplet generation protocols. Whether you’re exploring pioneering research or optimizing industrial workflows, these tips will equip you with the expertise to master droplet generation consistently. So, let’s get started and make sure your droplets are consistent and reliable, no matter the task at hand!

📏 Utilize Microfluidic Devices

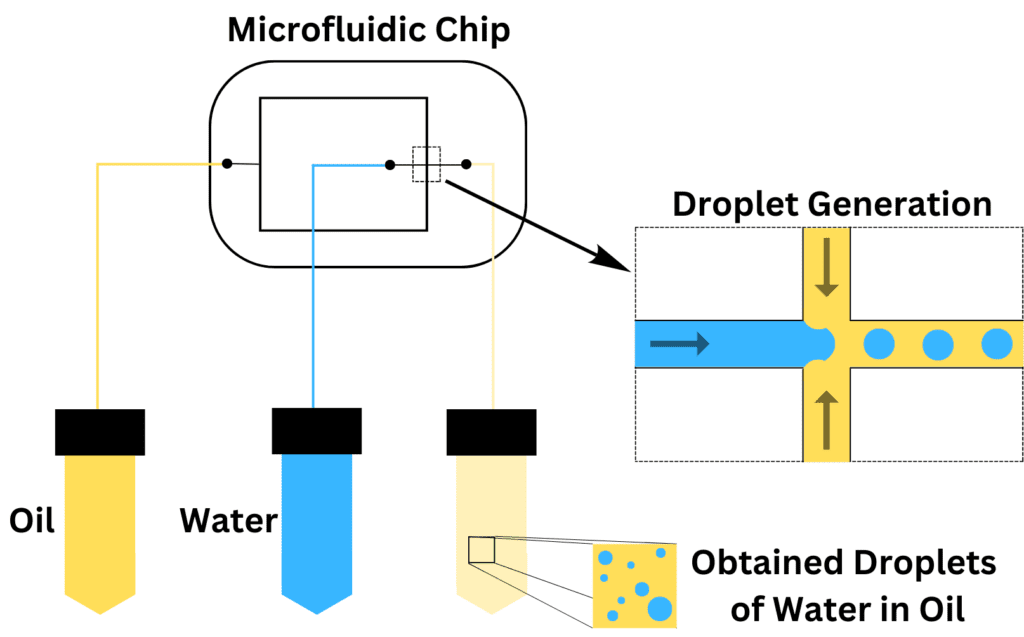

Microfluidic devices revolutionized droplet generation by providing precise control over flow rates, mixing, and droplet formation in a miniaturized setup. They enable reproducible droplet generation with remarkable accuracy and with minimal sample volumes, making them ideal for various applications such as drug delivery, chemical synthesis processes, and biological assays. These devices can handle multi-phase systems, allowing the generation of complex droplets with precise spatial and temporal control, essential for advanced applications including emulsification and encapsulation.

They have a relatively low production cost, a lower energy consumption and an improved environmental impact compared with other conventional processes, they are easy to produce/maintain and they usually allow optical investigation of the flow. Moreover, their integration with automation systems enables high-throughput droplet generation that facilitates rapid experimentation and analysis.

🚰 Choose the Right Nozzle

The geometry of the nozzle significantly influences the characteristics of the drops: their size, uniformity and dispersion pattern. From cylindrical to conical, various nozzle shapes impact the fluid dynamics differently yielding different droplet characteristics. The orifice size determines the droplet size with smaller orifices producing smaller drops. The compatibility of the material is crucial to prevent the degradation of the nozzle, ensuring consistent performance. A smooth internal surface minimizes turbulence and promotes therefore, uniform droplet generation. Nozzle designs resistant to clogging minimize maintenance by preventing the buildup of debris. The compatibility with the dispensing system ensures integration and operation.

Overall, selecting the right nozzle involves considering geometry, material, adjustability, clogging resistance, precision, and compatibility with the dispensing system to achieve optimal droplet generation performance across various applications.

🌊 Control Flow Rate

It is very crucial to control the flow rate in droplet generation as it directly impacts the size of the drops, their frequency and their uniformity. Generally, higher flow rates produce larger drops as the liquid volume per droplet increases and result in a higher frequency droplet generation, while lower flow rates yield less frequent droplet formation with smaller droplets.

In some droplet generation applications, it is important to keep the flow rate steady to make droplets of the same size that are evenly spaced. For others, the flow rates require adjustments according to the droplet application: fast flow rates might be needed for quick processing in some tests as in the case of high-throughput screening, while low flow rates offer finer control, especially for encapsulating single cells.

Overall, a precise flow rate control is essential for achieving the desired droplet characteristics.

WANT TO AMPLIFY YOUR DATA INSIGHTS?

Explore our microfluidic sensors for accurate analysis and real-time monitoring!💧 Optimize Liquid Properties for Droplet Generation

The properties of the liquids used profoundly affect the droplet generation:

- The viscosity of the liquid directly impacts the formation of droplets;

- high viscosity results in larger and more stable droplets

- lower viscosity yields smaller, faster moving and less stable droplets.

- The surface tension of the liquid affects the shape and the spreading of the drops;

- lower surface tension results in drops spreading evenly for coating

- higher surface tension keeps the drops separate as discrete drops (like raindrops on a window).

- The density of the liquid impacts the trajectory of droplets and the evaporation rate.

- The chemical composition impacts the stability and functionality of the droplets.

- The rheological properties of the liquid (viscosity and elasticity) help in predicting the behavior of the flow and ensure consistent generation of drops in various applications (e.g. emulsion formation).

Therefore, it is important to optimize these liquid properties to enhance droplet generation processes.

🧪 Optimize Surfactant Concentration

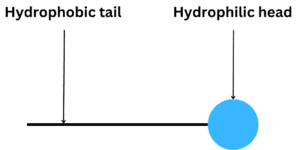

Surfactant molecules naturally adhere to the interface between oil and water, forming a layer that reduces tension and aids in droplet breakup. They consist of hydrophobic tails and hydrophilic heads, capable of stabilizing the liquid-liquid interface and preventing instabilities.

In droplet generation processes, surfactants improve droplet formation and stability by reducing surface tension, yielding smaller, more uniform droplets, and enhancing liquid wetting on substrates. However, an excessive surfactant use can lead to issues like excessive foaming, disrupting droplet formation and increasing costs and environmental concerns. Hence, a careful adjustment of the surfactant concentration is essential to optimize droplet characteristics while minimizing drawbacks associated with the excessive surfactant usage.

🌡️ Control Ambient Conditions

Controlling ambient conditions, including temperature, humidity and pressure, is essential for precise droplet generation as these conditions directly impact droplet size, stability and trajectory:

- Temperature plays a critical role in modifying liquid properties essential for droplet formation, including viscosity, surface tension, density and volatility.

- Humidity affects evaporation rates where higher humidity tends to slow down the evaporation, while lower humidity speeds up evaporation, which may influence the size, shape and distribution of droplets during deposition.

- Consistent pressure levels contribute to reproducible droplet characteristics by ensuring uniformity in droplet size, spacing and trajectory during formation.

- Proper airflow control minimizes disturbances (such as turbulence or fluctuations in air pressure) during droplet generation, especially in processes like inkjet printing or spray coating where disturbances in the airflow can cause droplets to deviate or collide with each other.

- Controlled lighting ensures accurate observation in optical-based techniques.

🫧 Monitor Droplet Formation

It is essential, to ensure the success of your experiments, to monitor the formation of your droplets. Observing the formation of drops closely and regularly makes it easier to identify arising irregularities and inconsistencies. Moreover, it allows assessing the size of the drops, their uniformity and the frequency of their formation. These parameters can be monitored and analyzed using different imaging techniques, mostly optical microscopy and high-speed imaging to capture real-time images of droplet generation.

Try to implement automated monitoring systems that will allow you to track the generation of drops over time leading to a precise control of your experimental conditions.

🔬 Consider Substrate Properties

Substrates must be durable and stable under operating conditions as the behavior of a droplet is significantly influenced by the properties of the surface onto which the droplet is deposited. These properties include:

- surface energy, that determines droplet spreading

- surface roughness, that affects droplet adhesion and distribution

- chemical compatibility, that prevents unwanted reactions between substrates and droplets

- porosity and absorption, that alter the droplet distribution

- optical transparency, that aids observation in microfluidics

- temperature sensitivity, that affects droplet adhesion and spreading.

Understanding and optimizing substrate characteristics enhance droplet deposition efficiency and maintain droplet quality.

🎨 Use Surface Treatments

Surface treatments are used to enhance droplet generation processes by modifying the properties of surfaces in contact with the liquid. These treatments aim to control droplet behavior, wetting properties, adhesion forces, and spreading characteristics. Examples include hydrophobic or hydrophilic coatings (e.g., for water-in-oil or oil-in-water emulsification, respectively), plasma treatments, and chemical functionalization (including coatings like fluoropolymers) that involves attaching specific molecules to the surface.

| Surface Treatment | Effects on Droplet Behavior |

|---|---|

| Hydrophobic Coating | Repels water, promotes rapid droplet formation |

| Hydrophilic Coating | Enhances wetting, ensures uniform droplet spreading |

| Plasma Treatment | Modifies surface chemistry, controls droplet behavior |

| Chemical Functionalization | Imparts non-stick properties, enhances chemical resistance |

By utilizing appropriate surface treatments, you can optimize droplet generation processes for various applications, such as inkjet printing, microfluidics, and biomedical devices, ultimately improving efficiency and reliability.

🧼 Maintain Cleanliness

Even in minute amounts, contaminants can significantly affect droplet formation and compromise your experimental results. Therefore, it is important to maintain cleanliness to ensure a consistent droplet generation.

Regularly clean the components of your system (including tubings, microchannels, surrounding surfaces, etc.) to prevent the accumulation of dust, residues or debris. For that, use appropriate cleaning agents and techniques that are suited for the material you are using. Make sure you thoroughly rinse the surfaces to remove all contaminants.

For more details about how to clean your microfluidic chip, check our blog post: How to clean a microfluidic chip?

💡 Conclusion

In conclusion, droplet generation encapsulates different considerations all related to precisely yield droplets with the needed characteristics. Using microfluidic devices, optimizing ambient conditions, maintaining cleanliness, understanding substrate properties, and monitoring droplet formation further elevate the efficiency and reproducibility of your droplet generation.

Through continuous experimentation, refinement, and implementation of best practices, we ensure that generating droplets becomes easier over time, promising a future filled with boundless possibilities 🚀.

Stay tuned for future content exploring advanced droplet generation methods and their diverse applications😉. Until then, don’t pop your drop 🫧!

📧 If you have any questions or feedback, please feel free to contact us at contact@darwin-microfluidics.com.