The subject of this review is to evaluate to what extent the true value of a characteristic can be measured. To answer this question, 2 criterias must be taken into account: the intrinsic characteristics of the instrument and the measurement process.

Accuracy of the measuring process

The measuring process is defined by its accuracy, i.e. the smallest change in the value of a characteristic, which is assumed to be stable and well-defined, that can be reproducibly detected by this process.

This accuracy will then depend on :

- the measuring device itself via its quality, complexity and condition and

- the conditions of its use, including the competence, skill and degree of attention of the person using it.

Concerning the part of the accuracy related to the measuring device, it comprises two factors which are:

- the resolution of the device, which is the smallest difference in value observable on its display

- its ability to provide the same value (= fidelity), or very similar values, during successive individual measurements of the same characteristic, carried out under the same conditions.

The accuracy of a measuring device is sometimes indicated in the operating instructions of the device. This accuracy is that which can be achieved under ideal conditions by an experienced and attentive user, but is often subjective.

Systematic error

Regardless of its accuracy, a device can be defective, or miscalibrated, or misused.

For example, with a digital display device, it may not indicate zero for a measurement of zero value, or it may display values multiplied (relative to " true " values) by a constant or function whose value remains close to unity. It is also possible that a change to a set-up during an experiment may change a parameter that influences the measurements (for example, the diameter of the tubing used when using a peristaltic pump).

In all these cases, a deviation from the value that would normally be measured occurs. This deviation, which is called systematic error, affects the accuracy of the measurement, i.e. the same deviation will occur at every repetition of the same measurement, and will be reflected directly in the value of the mean.

Experimental uncertainty

Experimental uncertainty is the magnitude of the random, unpredictable or indeterminate variation in the measured value of a characteristic of an object. Often this variation is predominantly associated with one or other of the following dimensions:

- the limited accuracy (resolution and/or precision) of the measurement process: this is the measurement uncertainty;

- instability, irregularity or poor definition of the object: this is the uncertainty of definition.

Whatever its source, uncertainty can never be eliminated from experimentation and, unlike systematic error, it cannot be corrected. It is therefore necessary to evaluate it well, so that it is correctly reflected in the results and taken into account in their interpretation.

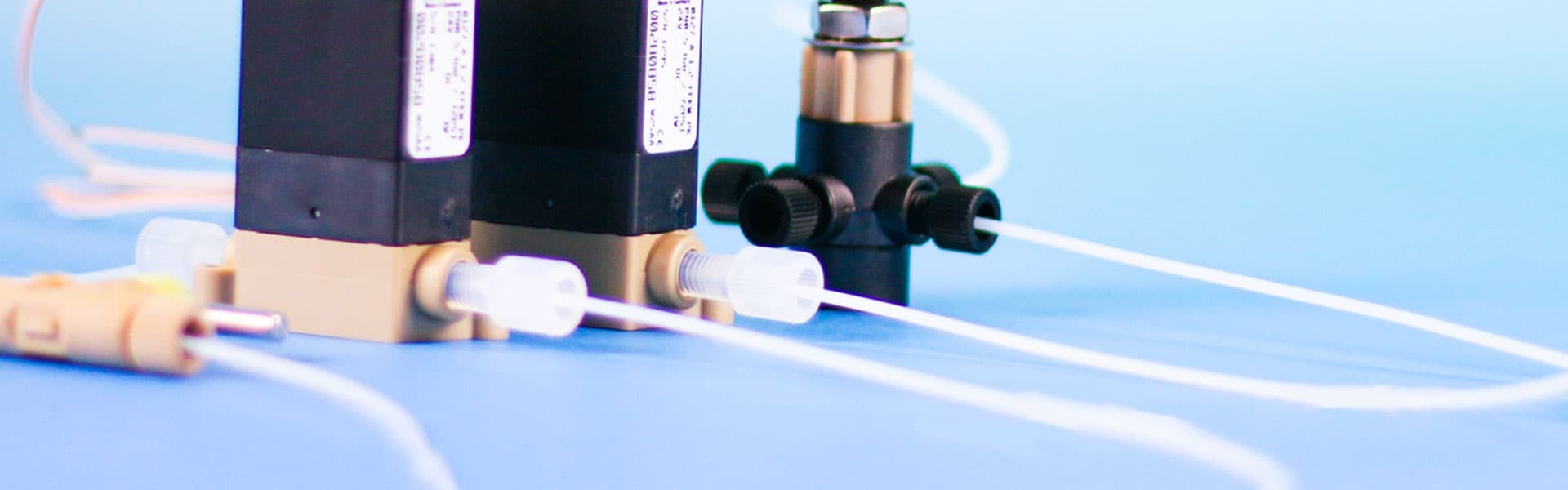

In a concern for transparency, Darwin Microfluidics strives to test the precision of the instruments we develop and distribute. Contact us if you have any question!