Microfluidic chips can provide a biomimetic environment for cell and tissue culture, preserving key aspects of the biological system while integrating downstream analysis. It is even possible to go further by integrating a continuous supply of nutrients via recirculation of the medium. In this tutorial, we will introduce the different recirculation techniques and what ways exist to achieve them.

Briefly, recirculation is usually achieved by using a peristaltic pump to return the outlet eluent to the inlet tank so that the suspension can pass through the device again.

Advantages of recirculation in cell culture:

- The integration of recirculation within a microfluidic device will allow us to get a little closer to reality as well as for the understanding of drug absorption, distribution, metabolism, and elimination. Indeed, every organ, tissue or cell of the human body is continuously irrigated via body fluids, whether in an open circuit (saliva, gastric fluid, urine…) or in a closed circuit (blood, lymph, pleural fluid…).

- Depending on the installation, it can allow the elimination of the waste, which can considerably improve the performance of the experiment and, once again, mimic reality.

- The recirculation technique also saves culture medium, which can be very expensive for primary cells, and enriches the medium with cell secretion factors. Nevertheless, it should be noted that closed circulation requires the medium to be supplied with CO2 inside the chip. This can be done using either a gas-permeable material or a CO2-independent medium for short periods (about 2 hours).

Recirculation with a peristaltic pump in cell culture

Peristaltic pumps are widely used in cell culture, being easy to use and connect. Peristaltic pumps can be used in a variety of situations, but in most cases to recirculate fluid through a chip. The number of samples that can be infused in parallel generally ranges from 1 to 24, depending on the number of channels on the pump head.

By definition, peristaltic pumps provide pulsating flow. The frequency and amplitude of the oscillations vary from one pump to another depending on the number of rollers, their frequency of rotation and the diameter of the tubing used. Most peristaltic pumps are controlled by a software that allows protocols such as periodic injection or simple flow variations to be automated.

In most cases, all tubes are wound around a rotor and therefore provide the same flow rate in each chip, which may be limiting for some studies. However, new models are coming onto the market that allows several samples to be infused at the same time independently. Today, specific tubing formulations for peristaltic pumps considerably increase their lifetime, ensuring good and reproducible performances.

Media recirculation is also possible with a miniaturized on-chip peristaltic pump based on pneumatically controlled microchannels and was reported by Balagadd´e et al. [Balagadd´e et al., Science 2005].

Other set-ups

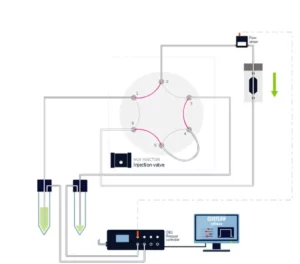

Beyond peristaltic pumping, it is possible to create an injection loop using other pumping technologies. This method consists of a network of inputs/outputs that can be connected together in a configuration allowing a recirculating set-up with a flow rate always going through the microfluidic device in the same direction.

To perform this injection loop, you will need :

- Pressure controller (Microfluidic flow control system 4 channels)

- Flow sensor (MFS Microfluidic Thermal Flow Sensor)

- Injection valve (MUX Recirculation)

- Microfluidic device (Microfluidic Organ-on-a-Chip)

- Sample reservoirs (Microfluidic Reservoir)

By using a pressure controller, the flow will be all the more regular and impulse-free unlike the use of the peristaltic pump. This set-up will allow the complete automation of your experiments, whether they last 2 hours or 1 week with limited media volumes or more advanced applications such as the modelling of complex biological flow models.