Peristaltic pumps are devices used for pumping small volumes of liquid in microfluidic systems. This comprehensive guide will cover the basics, including the construction, working principle, and applications of these pumps.

Whether you’re a researcher or a student, this article will provide you with everything you need to know about peristaltic pumps.

What are microfluidic peristaltic pumps and how do they work?

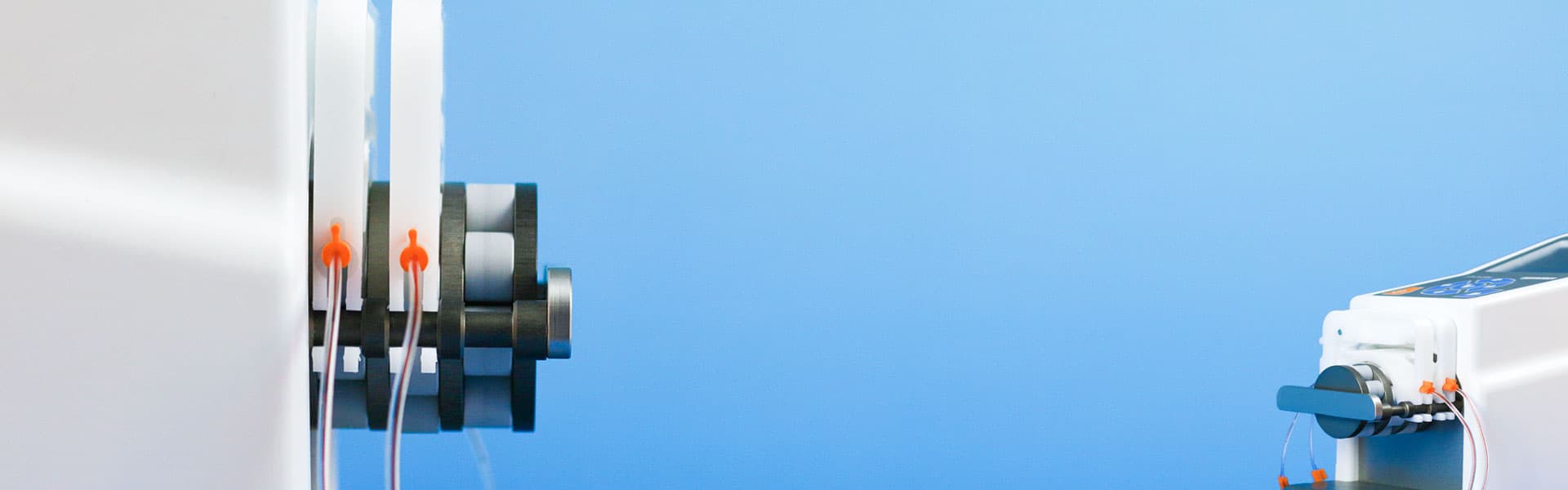

Peristaltic pumps are a type of mechanical pump designed specifically to handle liquids in small volumes and with precise flow control. They work by forcing liquid through flexible tubing rather than valves, creating peristaltic action.

These peristaltic pumps reduce the risk of contamination, making them ideal for use in sensitive environments. The pump head applies pressure to the flexible tubing, squeezing and pushing any liquid within it through the length of the tubing and controlling its speed.

Additionally, these peristaltic pumps don’t have any seals and have minimal maintenance costs, making them a highly desirable solution for laboratories and other controlled environments. By understanding their components and operation cycle, you can determine how to effectively use peristaltic pumps in your microfluidic applications.

What are the components of a peristaltic pump?

A peristaltic pump has three main parts: a pump driver, a pump head, and some special tubing:

Pump driver

A pump driver contains the motor and controller of the peristaltic pump. One or several pump heads can be attached to it.

Pump head

A pump head is the part of a peristaltic pump that is attached to the pump driver. It is usually constructed from metal or plastic and is designed to keep the pump rollers in place as they rotate. A broad range of pump heads exists, with 1 up to 12 rollers, one channel or multichannel capability, and different tubing compatibilities.

Tubing

Peristaltic pump tubing is a special tubing used inside of a peristaltic pump. Generally, a given pump head only accepts a restricted range of tubing sizes. Some pump heads only accept tubing with stoppers to hold it in position. Depending on the tubing you choose, you may get more or less pulsing in the fluid as it moves through the pump.

The benefits and disadvantages of using a peristaltic pump

✅Peristaltic pumps are the perfect solution for many industrial and lab situations:

They contain a pump head that is easy to access and replace, meaning minimal downtime for maintenance tasks. This makes them one of the most cost-effective solutions available.

Peristaltic pumps are incredibly reliable, with very low failure rates due to their simple construction, making them an ideal choice for many applications where dependability is essential.

Open reservoirs make them ideal for recirculation.

❗When it comes to using a peristaltic pump, there are several cons that should be taken into account:

First, the tubing must be replaced regularly in order to ensure proper operation, as it will eventually wear out from regular use.

Peristaltic pumps cannot reach very low flows (less than 1 µL/min).

When using a peristaltic pump, it is important to consider the pulsatility of the flow rate caused by the rollers.

💡Pulsatile flows can be desirable in certain applications, such as sample collection, or organ-on-chip. However, they can also cause problems such as inaccuracy and flow fluctuation, especially for very low-flow applications.

Overall, microfluidic peristaltic pumps are highly useful and reliable devices that can provide accurate flow control in different types of applications. They require minimal maintenance, making them an ideal choice for laboratories and other controlled environments.With this guide, you now have a better understanding of the basics behind these pumps, so you can make an informed decision when considering peristaltic pumps for your applications.

The different types of peristaltic pumps

The discussion about difference between hose pumps and peristaltic pumps is often a topic of debate, yet there are very few actual differences between these two types of pumps. In the most basic sense, peristaltic pumps use a peristaltic action to move fluid, while hose pumps use the same mechanism to squeeze a reinforced hose.

The term "hose pump" is mostly used to describe peristaltic pumps that are designed to move large volumes of liquid or slurry at high pressure, making them well-suited for many applications such as pumping abrasive and corrosive media. These are typically industrial peristaltic pumps.

There are many types of peristaltic pumps and they all have unique components, so we will describe those used to handle small volumes.

Depending on the application, peristaltic pumps might come with various features like a pump head and tubing design tailored to deliver specific amounts of flow, as well as accessories capable of interfacing with the control system.

Some peristaltic pumps even feature manual controllers, meaning all functions can be adjusted without connecting to a computer. Ultimately, knowing which peristaltic pump type suits your needs will help ensure efficient operation and durability.

Single-roller peristaltic pump:

A single-roller pump is a type of peristaltic pump with a simple design and construction that makes it both reliable and cost-efficient. The pump head has just one roller that presses against the flexible tubing, squeezing and pushing liquid through it while controlling the speed or flow rate.

❗We do not recommend its use for microfluidics applications❗

Multi-roller peristaltic pump:

Multi-roller peristaltic pumps are a type of pump that is designed for more precise and efficient flow control. This type of pump consists of two or more rollers that press against the flexible tubing, squeezing it as they rotate. The shape, speed and number of rollers can all be adjusted to improve efficiency and flow rate accuracy.

You should keep in mind that the more rollers, the less pulsatility!

The most versatile type to fit your microfluidic applications 😉

Independent channel peristaltic pump:

Independent channel peristaltic pumps are an advanced type of pump that offers a unique advantage over traditional models: they are capable of controlling multiple channels of fluid simultaneously.

This configuration can make you save a significant amount of space on the laboratory bench. Not only is this useful in labs where space is limited, but it also allows for more efficient operation.

How to choose the right peristaltic pump for your needs?

Choosing the right peristaltic pump for your needs doesn’t have to be complicated. Start by determining the required flow rate and volumes, then consider the materials that will come into contact with the pumped fluid.

The pump head is one of the most important features to consider when selecting a peristaltic pump – you’ll want to make sure that it’s compatible with the other components in your system. Furthermore, ensuring compatibility between the pump tube material and your fluid is essential; various types of peristaltic pumps are designed for different liquids, so research thoroughly before getting started.

Last but not least, your budget will be an important condition. Many brands offer features that are not necessarily in line with your project and this can be reflected in the final price.

Fortunately, for some time now, the number of models has only increased. In most cases, you will find a model that will fit your requirements.

We do offer a wide range of pumps, so don’t hesitate to take a look 😉

💡 Tips for using a peristaltic pump

Using a peristaltic pump correctly can make all the difference when it comes to pumping small volumes of liquid. Firstly, always ensure that the peristaltic pump is securely connected to the required power source and that the tubing is inserted properly into the pump head.

Secondly, consider choosing a peristaltic pump that has adjustable settings as this can allow for more flexible use, allowing you to customize settings such as flow rate and rotation speed depending on your specific project requirements.

Finally, remember to regularly check for signs of wear and tear in both the tubing and the peristaltic pump itself to guarantee efficient performance whenever you need it, so that your peristaltic pumps will remain reliable and accurate for years to come!

🧠 What you have to remember

Peristaltic pumps are a type of positive displacement pump that is ideal for pumping small volumes of liquid in systems. These pumps offer many benefits, including being self-priming, adaptable to different system pressures, and portable.

The right pump for your needs will depend on the application and desired flow rate.

When using a peristaltic pump, be sure to keep the following tips in mind:

- Use clean tubing free of debris or damage.

- Ensure proper alignment between all parts of the pump.

- Inspect the pump regularly for leaks or other issues.

With this information in hand, you should be well on your way to choosing and using the perfect peristaltic pump for your needs! 😁