When beginning to work with microfluidics, you may be confused by the number of connection types for your chip, your tubes, and your pump. Indeed, microfluidics has borrowed these standards from different fields, such as HPLC and medicine, and each manufacturer has his preferences for one connection type or the other.

In this tutorial, we will define the types of fittings & connectors that are mostly used in microfluidics, and explain how to choose them depending on three principal parameters: the tubing used, the pressure applied in your microfluidic system, and what you need to interface (chip, syringe…).

The different types of fittings & connectors in microfluidics

Generally speaking, the following connectors have been chosen for microfluidics in order to get the smallest internal volume possible while ensuring leak-free connections. The connectors in microfluidics are divided into two categories: threaded and Luer. We will then see how to directly connect a PDMS chip to rigid or soft-walled tubing, and the less-used microfluidic fittings & connectors.

Threaded connectors

Threaded connectors are widely used in high-pressure applications, such as HPLC or GC. In microfluidics, they ensure leak-free connections and resistance to high pressure (> 100 bar), while being really convenient for connecting rigid tubing (such as PTFE, FEP, PEEK…).

What we call "fitting" is the system comprised of a nut and a ferrule. The nut is screwed in the receiving thread, while the ferrule is compressed by the screwing and seals the connection.

While these fittings and connectors are mostly fabricated PFA or PTFE, they can be found in polypropylene for low-pressure applications, or PEEK for the most demanding ones.

| Pros | Cons |

| Easy to use: just screw the connector to get a leak-free and resistant connection (> 100 bar) | The nut + ferrule assembly only works with rigid tubing, and not with silicone, Tygon, etc. Threaded to barbed adapters exist to connect soft-walled tubing, but with limitations |

| Available in different materials (Delrin, PFA, PTFE, PEEK…) | Not a standard for off-the-shelf microfluidic chips |

1/4-28

The most used threaded connectors in microfluidics. With a diameter of 1/4 inch (6.35 mm) and 28 threads by inch, they are particularly useful when connecting a 1/16" OD (1.6 mm) or 1/8" OD (3.2 mm) rigid tubing.

10-32

These connectors are used as an alternative to 1/4"-28 UNF for their smaller size (diameter of 0.19 inch or 4.82 mm, 32 threads per inch). Available for 1/16" OD tubing, these 10-32 connectors can also fit 1/32" OD tubing.

6-40

The smallest standard connectors used in microfluidics, with a diameter of 0.138 inch (3.50 mm) and 40 threads per inch. These fittings are also coupled with ferrules, and are mostly used with 1/32" (0.8 mm) OD tubing.

💡 Tip: The more threads on the fitting, the more pressure it can handle! You should then consider the last number (28 in "1/4-28" or 40 in "6-40") which gives you the number of threads per inch. In microfluidics, high pressure is not a key requirement, and the selection of a fitting size mostly depends on its convenience.

Threaded to barbed adapters

As seen above, the nut + ferrule assembly is not compatible with soft-walled tubing. However, some solutions exist, such as Threaded to Barbed adapters (see image below). The smallest arrow being for tubing with an inner diameter of around 1.2 mm, it will not be possible to connect a tubing with a smaller inner diameter. Also, it is impossible to work at high pressure with this fitting, since the tubing would pop out of the adapter.

Luer connectors

Inherited from the world of syringes and needles, Luer connections are particularly convenient for "plug-and-play" microfluidics, allowing leak-free and easy connections. Two main Luer connections are used:

- Luer Slip fittings are pressed together and held by friction (no thread),

- Luer-Lok fittings, also commonly referred as Luer Lock, are Luer Slip connections with a tabbed hub on the female fitting which screws into threads in a sleeve on the male fitting.

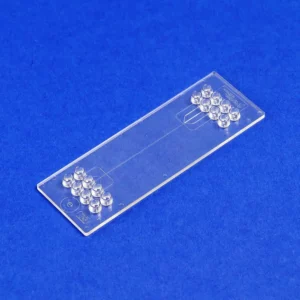

The mirofluidic chip manufacturer ChipShop has developed standard chips using a new type of Luer standard: mini Luer. Using the same principle as Luer for plug-and-play connections, they have smaller dimensions to fit on chips the size of a microscope slide (75 mm x 25 mm).

| Pros | Cons |

Very easy to use For Luer Lock fittings, the connection is secured and tight | Luer Slip fittings are less resistant to high-pressure (max. pressure is 2 bar) than threaded connectors. The added thread of the Luer Lock fittings helps reaching higher pressures. |

Luer Slip fittings have a small footprint, making it easy to create a connection to a microfluidic chip | Luer Lock fittings have a large footprint, not compatible with some microfluidic chips |

| Direct connection to adapters for soft-walled tubing (silicone, Tygon…) | Not convenient for connection to rigid tubing (PTFE, FEP, PEEK…) |

💡 Tip: Having a Luer Slip connection instead of Luer Lock on your chip is not a problem when working with microfluidics! Usually, the pressure in the system is low enough to ensure a good connection in every part. However, it is always better to use a Luer Lock syringe in order to secure the connection.

How do you connect these Luer ports to your tubing then? In fact, it is easy to connect soft-walled tubing, such as silicone or Tygon: you can find many connectors with an arrow depending on the tubing inner diameter, the minimum being around 1 mm. For smaller tubing sizes, as Luer are generally used with needles on syringes, it is possible to connect a needle to the Luer fitting easily.

Direct connection

On PDMS chips, it is possible to directly connect the tubing to the microfluidic chip via the punched holes. However, the tubing must be rigid (e.g. PTFE).

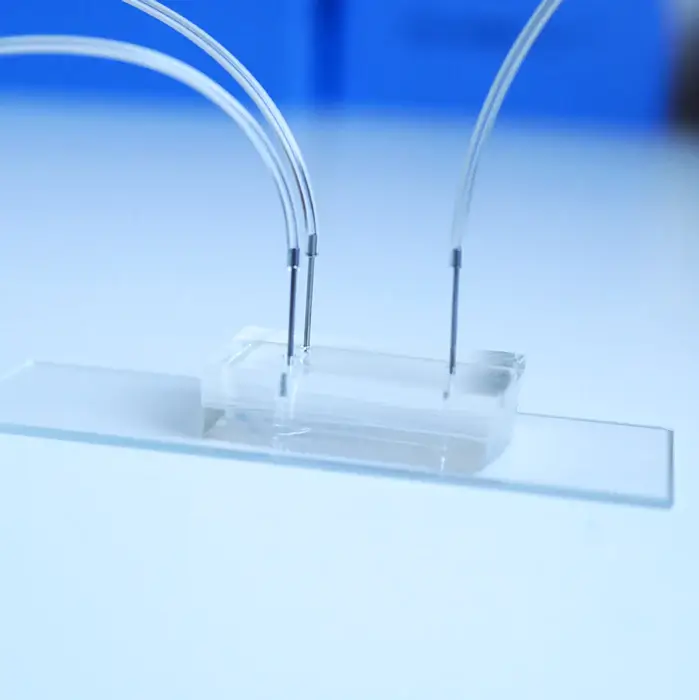

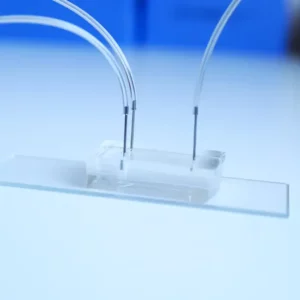

Alternatively, soft-walled tubing can be connected to PDMS chips via needles, as in the image below.

Other types of connectors

These connectors are less used in microfluidics, but you may be able to find them for specific applications.

Push-in

Push-in fittings are reliable and easy to use: once the tubing pushed into the connection port, the tubing is held tight. Mostly used for pneumatic connections, push-in can also be interesting for liquid connections, but the tubing diameter needed is generally higher than the tubing used in microfluidics.

6-32

As an alternative to 6-40 fittings, 6-32 can also be found in microfluidics. Mostly used for capillaries (360 µm OD), they are convenient thanks to their small footprint.

How to choose the good fittings & connectors in microfluidics?

The following table sums up the strengths and weaknesses of the most commonly used connectors in microfluidics.

| Connection type | Strengths | Weaknesses |

| Threaded (nut + ferrule): 1/4-28, 10-32, 6-40, etc. |

|

|

| Threaded to Barbed |

|

|

| Luer Slip |

|

|

| Luer Lock |

|

|

| Direct connection |

|

|