Microfluidics designates the science but also the techniques behind flow managing at the micro-scale. At these sizes, fluids’ dynamics radically changes compared to everyday life: for instance, water streams are laminar, meaning that they do not mix or form vortexes or eddies. This an other unique features are at the basis of the revolution brought by microfluidics in science. In order to control and confine fluids at the micro-scale, microfluidic chips are used.

What is a microfluidic chip?

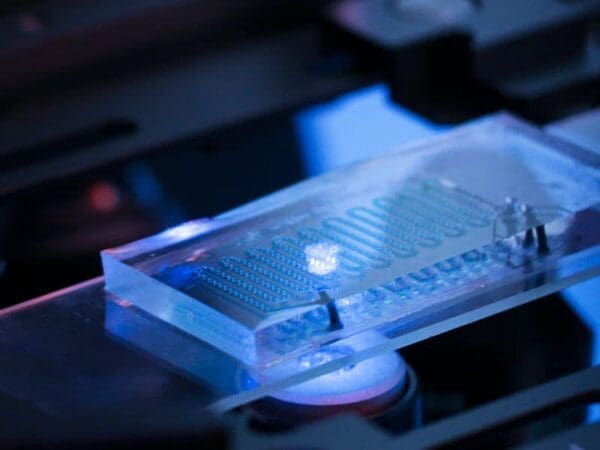

These are devices where patterns of microchannels are either molded or engraved. In addition, active or passive flow-control elements, such as membranes or valves, can be implemented onto the chip in order to carefully manage fluids. Therefore, microfluidic chips allow to integrate several functions that generally require an entire laboratory, in a single micro-seized device. That is why microfluidics, and in particular, microfluidic chips are often referred to as "Laboratory-on-chip". In the following, a brief overlook of the most common materials employed to manufacture microfluidic chips will be provided.

Materials for microfluidic chips

Over the years several materials, such as glass, silicon and polymers, have been employed to manufacture microfluidics device. These can be primarily categorized into: inorganic, polymeric and paper. Obviously, there is no such thing as a "perfect" material as everyone of them has some advantages and drawbacks when employed in microfluidics. Ultimately, is the application which guides the researcher in the selection. In this chapter the most common material used in microfluidics will be briefly reviewed. The more curious reader can find more information in many excellent reviews published on the topic, such as the ones by Nge et al. 2013 and We et a. 2013.

Polymers

Polymers are widely used in the fabrication of microfluidic devices because of their good bio-chemical performance and low-cost. Among them, one of the most used is PDMS. The acronym PDMS indicates the Polydimethylsiloxane, a mineral-organic polymer of the siloxane family. This material can be found in food as an additive (E900), in cosmetic products and lubricating oils. The reasons that make PDMS a very good material for chip fabrication are several, the main are here summarized:

- Transparency: micro-channels and their content can be seen directly

- Elasticity: PDMS is quite elastic and this propriety can be used for various applications, e.g. valve integration through channel deformation. Furthermore its elasticity can be “tuned” using cross-linking agents

- Cost : PDMS is much more less expensive than other materials used for microfluidic chip fabrication;

- Permeability: PDMS is gas permeable which can be used in cell culture, gas sensors, etc…

Obviously, there are also shortcomings in using PDMS for microfluidic chip fabrication. Some examples are: the aging of the material which limits the performance of the chip during the years and the poor chemical compatibility with many organic solvents which makes PDMS suitable mainly for aqueous applications.

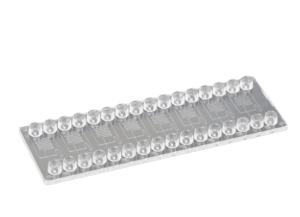

Furthermore, PDMS absorbs hydrophobic molecules and water vapor that can be then accidentally emitted during the experiment. Another drawback of PDMS microfluidic devices is the impossibility to implement electrodes within the chip, even if this can be worked around by putting the electrodes in the glass cover slide instead of the chip itself. More can be found on PDMS and its application to microfluidics at Elvesys site. As mentioned above, while PDMS allows fast and easy microfluidic chip fabrication, it has various shortcomings that prevent its use in some application. In order to come over these drawbacks, but still benefit of inexpensive and fast production, other polymers can be used to build microfluidic devices. One example of another polymer used for microfluidic chip is Polystyrene (PS) which is a polymer of standard use in drug research for cell-culture dishes. PS is optically transparent, biocompatible, inert, rigid, and its surface can be readily functionalized.

💡 its hydrophobic surface can be easily made hydrophylic by various physical and chemical means, including:

corona-discharge, gas plasma and irradiation. Others often used polymers for microfluidic devices are Polymethylmethacrylate (PMMA) and Polycarbonate (PC). PC presents a better thermal resistance than PMMA and thus it can be used in a wider range of temperature. PMMA is an elastomer with little deformation in comparison with PDMS and hence is employed when rigidity is required, e.g. for construction of canalization of microvalves. Should you want to learn more about hydrophilic/hydrophobic coating, take a look at our complete review here! 😉

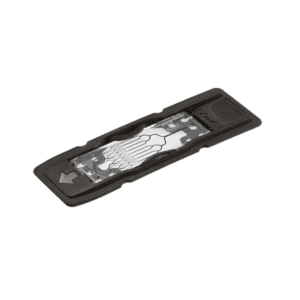

Silicon and Glass microfluidic chips

One of the first materials used in microfluidics was silicon. The reason of this relies on the deep link between the first microfluidics chips and the microelectronic industry, where silicon was and still is one of the most used materials. Advantages of silicon in microfluidic applications lie in its thermal conductivity, surface stability and solvent compatibility. The main drawback of silicon microfluidic chips is its optical opacity in the visible electromagnetic range that makes optical detection impossible.

Another pioneer material in microfluidic chip fabrication has been glass. This material has the same above-mentioned advantages of silicon. In particular, its well known surface chemistries, superior optical transparency and excellent high-pressure resistance make it the best choice for many applications. Glass is also biocompatible, chemically inert, hydrophilic and allows efficient coatings. The main shortcoming of glass microfluidic chips it’s the rather high cost of the raw material.

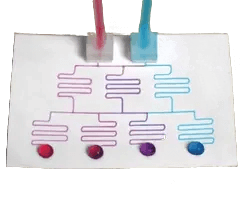

Paper-based microfluidic chips

Lately, also paper has been taken into account as a potential material for microfluidic chip fabrication. The main reason for that it is because paper is a very cheap raw material. However, the advantages of using paper for microfluidic devices applications go beyond just the extreme low costs. Indeed paper is thin, lightweight and easy to store, manipulate and transport. Furthermore, it is compatible with biological samples and can be chemically treated in order to bond with molecules or protein. Last but not the least, paper is easy to disposal after use which makes it a very environment-friendly material for microfluidic chips. The main shortcomings when using paper based microfluidic device is the difficulty in pattering the channels on the chip. Indeed, there is just not the “perfect” patterning method as each one implies trade-offs between cost, convenience and resolution that have to be evaluated case by case.