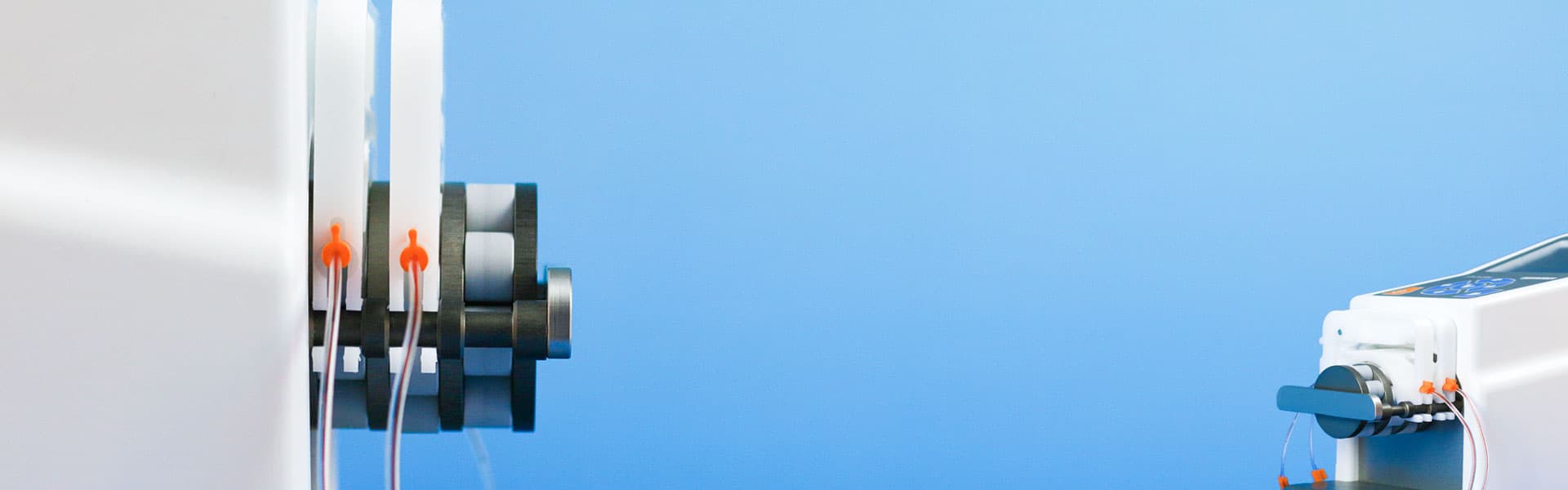

Masterflex is renown for its broad range of peristaltic pumps. Reliable and accurate, they are widely used in laboratories to precisely dispense or transfer fluids from a few microliters to dozens of liters.

Masterflex L/S range offers all the components required to dispense liquids for low-flow and laboratory applications. A complete peristaltic pumping system contains the following components:

- Peristaltic pump drive.

- Pump head.

- Tubing

The choice of the right pump head is critical, as it is the design and features of the head that makes it relevant (or not) for your application. You can also read our complete guide on peristaltic pumps here!

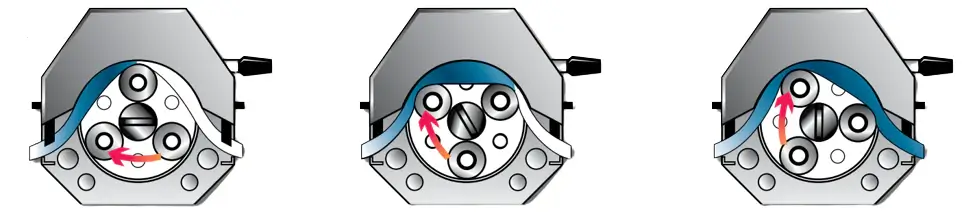

How do pump heads work?

- The tubing is placed in the tubing bed (between the rotor and the housing) where it is occluded.

- When the rotor turns, the rollers move across the tubing, pushing the fluid. Once the tubing recovers its shape, it creates a vacuum which draws fluid.

- This creates a "pillow" of fluid between the rollers. Flow rate is determined by multiplying speed by the size of this pillow.

How to choose your Masterflex L/S pump head?

- Define the flow rate required for your application. Some pump heads are more efficient at low flow rates, other more performant at higher flow rates.

- Will the pump head be exposed to harsh chemicals/environment? If yes, consider choosing housing and rotor materials that are resistant to these external constraints.

- Does the accuracy/pulsatility of the flow have an impact on your experiment? If yes, you should choose a pump head with more rollers, which will minimize the pulsation and increase its accuracy.

- How many channels do you need? Multichannel pump heads (up to 32 simultaneous channels) are extremely convenient to multiplex your experiments, but also more expensive and less versatile compared to separate pump heads.

Occlusion types

Occlusion defines how the tubing is "squeezed" by the rollers. It has an impact on the tubing performance and output flow.

- Standard fixed occlusion: occlusion is fixed at slightly different levels for each tube size to maximize its performances (flow, vacuum, tubing life). Pump heads with this occlusion type generally only accept one tubing size (e.g. Standard pump head).

- Average fixed occlusion: occlusion is fixed at an average level for several tubing sizes, allowing for fast tubing change and compatibility with different tubing sizes without changing the pump head.

- Adjustable occlusion: occlusion can be adjusted by the operator for optimal pump performance (e.g. Easy-Load II or Cartridge pump heads).

Materials

Masterflex pump heads are made of 3 main parts: the rotor, the rollers, and the housing. While some materials are chosen for their resistance to harsh environments, others increase the pump head life or optimize its efficiency.

Pump housing:

- Polycarbonate (PC): for general applications, translucent

- Polyphenylene sulfide (PPS): best protection against corrosive fluids/vapors

- Stainless steel (SS): resistant to corrosive fluids

- Polyarylamide (PARA) : high rigidity and smooth surface

- Aluminum: resistant to corrosive fluids

- Glass-filled nylon PA: high rigidity and mechanical strength

Roller/rotor:

- Plated cold-rolled steel (CRS): for general applications

- Stainless steel (SS): resistant to corrosive fluids, highest lifetime

- Aluminum: resistant to corrosive fluids

Compatible tubing for L/S pump heads

L/S pump heads are compatible with L/S tubing, but not all sizes. The following tables give the correspondance between tubing name and nominal inner diameter (ID), along with the compatibility of these tubing sizes with Masterflex L/S pump heads.

| L/S Precision tubing | L/S High-performance Precision tubing | |||||||||

| L/S 13 | L/S 14 | L/S 16 | L/S 25 | L/S 17 | L/S 18 | L/S 15 | L/S 24 | L/S 35 | L/S 36 | |

| ID (mm) | 0.8 | 1.6 | 3.1 | 4.8 | 6.4 | 7.9 | 4.8 | 6.4 | 7.9 | 9.7 |

| L/S pump head | Microbore pump tubing | L/S Precision tubing sizes | L/S High-performance Precision tubing sizes | ||||||||

| L/S 13 | L/S 14 | L/S 16 | L/S 25 | L/S 17 | L/S 18 | L/S 15 | L/S 24 | L/S 35 | L/S 36 | ||

| Standard | ✔️ | ✔️ | ✔️ | ✔️ | ✔️ | ✔️ | ✔️ | ✔️ | ✔️ | ||

| Easy-Load | ✔️ | ✔️ | ✔️ | ✔️ | ✔️ | ✔️ | ✔️ | ✔️ | |||

| Easy-Load II & 3 | ✔️ | ✔️ | ✔️ | ✔️ | ✔️ | ✔️ | ✔️ | ✔️ | ✔️ | ✔️ | |

| Multichannel | ✔️(2-stop) | ✔️ | ✔️ | ✔️ | ✔️ | ✔️ | ✔️ | ||||

| Multichannel Cartridge | ✔️(2-stop) | ✔️ | ✔️ | ✔️ | ✔️ | ✔️ | |||||

| High-Performance | ✔️(HP) | ✔️(HP) | ✔️ | ✔️ | ✔️ | ✔️ | |||||

| Minicartridge | ✔️(3-stop) | ||||||||||

Masterflex L/S pump heads comparison

Masterflex offers a broad range of pump heads, each with its own features. You will find below a comparison of Masterflex L/S pump heads, with their main specifications and key features.

| Flow rate from 0.02 to 600 rpm (mL/min) | Number of rollers | Multichannel or stackable | Housing/roller materials | Special features | |

| Standard | 0.001 to 2900 | 3 | Stack up to 4 heads | PC/CRS, PC/SS or PPS/SS | Low cost, high precision and accuracy. Best choice for dispensing application. One head accepts one tubing size. |

| Easy-Load | 0.001 to 2300 | 3 | Stack up to 4 heads | PSF/CRS, PSF/SS or PPS/SS | Very fast tubing changes. One head accepts many tubing sizes. Change tubing without dismounting pump head from drive. |

or | 0.001 to 2900 | 4 | Stack up to 4 heads | PPS/CRS or PPS/SS | Same as Easy-Load + automatic tubing retention and higher flow rates. Models with adjustable occlusion. |

| Easy-Load 3 | 0.001 to 2900 | 3 | Stack up to 4 heads | PP and nylon/CRS or SS | Easiest tubing change with automatic tubing retention, same side tubing entry/exit. Mount and stack heads without tools or hardware. |

or | 0.00005 to 2300 | 3 or 6 | Stackable 1 to 32 channels | Aluminum/SS | Synchronous flow from up to 32 channels without cartridges. Used with two-stop tubing. |

or | 0.00001 to 1700 | 3, 4 6 or 8 | Not stackable 1 to 12 channels | PSF/SS or PSF/Rulon | Synchronous flow rate from each channel using cartridges. Cartridges snap in and out quickly for multichannel applications. More rollers reduce pulsation in the output flow. |

| High-Performance | 0.018 to 3400 | 3 | Not stackable Not multichannel | Polyester, SS, PPS/SS | Accepts all High-performance tubing sizes. Highest flow rates of any L/S pump heads. Sames side tubing entry/exit. |

| PTFE-Tubing | 0.001 to 65 | 6 | Not stackable Not multichannel | Aluminum, acetal/SS | Rigid PTFE tubing is the only wetted material. Pressure capability to 6.9 bar (100 psi). |

| Minicartridge | 0.002 to 195 | 6, 8 or 12 | Not stackable 1 to 8 channels | Aluminum/Nylatron | High precision on low flow rates up to 8 channels with 3-stop tubing. More rollers reduce pulsation in the output flow. |

| Cytoflow | 0.03 to 7600 | 2 or 3 | Not stackable Not multichannel | Aluminum | Designed specifically for pumping live cells and shear-sensitive fluids in biopharma and microbiology applications. |

If you have any questions about the Masterflex range or need some help choosing the best peristaltic pump for your application, do not hesitate to contact us!