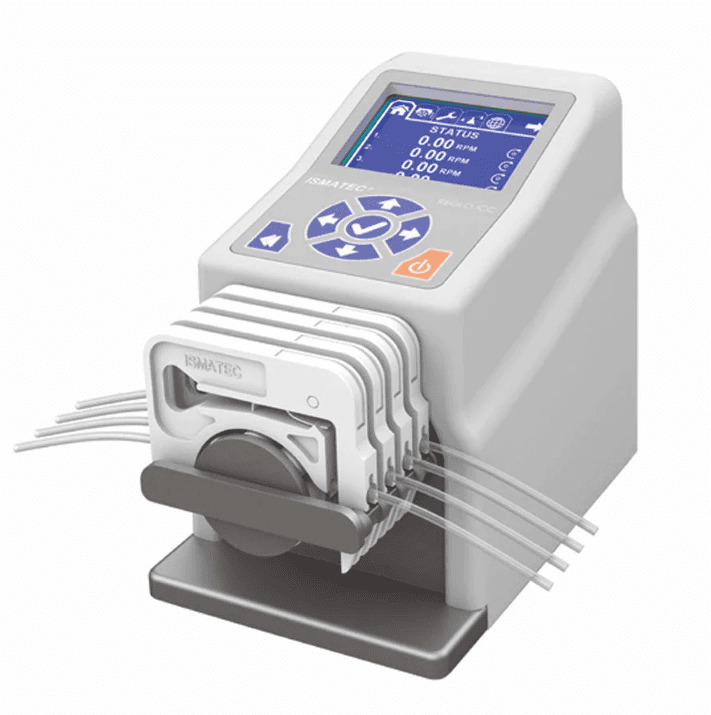

The Reglo ICC (Independent Channel Control) peristaltic pump by Masterflex Ismatec is a high-precision instrument engineered to deliver unparalleled control and accuracy in fluid dispensing and transfer. It stands out with its ability to independently control the direction and speed of up to four channels, each with unique programs for start, stop, calibration, and more.

With a working flow rate range of 0.001 to 35 mL/min per channel and customizable pulsation levels, this pump offers the flexibility needed for a variety of applications. The intuitive digital interface and RS-232 computer connectivity allow for the creation of complex pumping sequences and the control of multiple pumps simultaneously.

In this blog post, we will explore how to control the Reglo ICC peristaltic pump using the Reglo ICC serial command protocol via two programming platforms: Python and Matlab.

TABLE OF CONTENTS

Why Choose the Reglo ICC Peristaltic Pump ?

The Reglo ICC peristaltic pump is versatile and user-friendly, and it stands out as a top choice for fluid handling needs in laboratories and industrial settings alike. Here are some key advantages:

- Independent Channel Control of up to four channels, each with its own program, flow rates and directions simultaneously.

- High Accuracy and Reproducibility ensuring precise and consistent fluid dispensing by minimizing tube-to-tube differences.

- Adjustable Pulsation and Flow Range with 6, 8, or 12 rollers used to adjust pulsation and flow range (more rollers result in less pulsatility and lower flow rates).

- Versatile Control Options via its digital interface or RS-232 connection (up to eight daisy-chain pumps).

- Comprehensive Operating Modes including continuous dispensing at a set rate, dispensing a volume over a specified period, calibrating each channel, and more.

What do you Need to Communicate with the Reglo ICC Pump ?

To communicate with the Reglo ICC peristaltic pump you will need a few key components:

- A Reglo ICC pump with a pump head and a tubing of your choice,

- A mini-USB/USB cable or a DB9 connector (wired to an RS-232 control module) allowing for serial communication and enabling data transfer between the syringe pump and the computer,

- A programming platform (Python and Matlab in the case herein) or a terminal emulator,

- A basic understanding of the Reglo ICC command serial protocol explained below 👇 and detailed in the pump’s user guide.

How to Set Up the Communication Port ?

Before you can start sending and receiving data from the pump, you need to set up the communication port correctly. Here are the steps to follow:

- Connect the mini-USB/USB cable or DB9 connector to the serial port on the rear of the pump and the corresponding port on the computer.

- Turn on the pump.

- Identify the serial port name assigned to the connection on your computer (e.g., COM4 for Windows or /dev/ttyUSB0 for Linux). You can typically find this information in the device manager or by using terminal commands.

- Ensure that the serial port settings match the specifications of your syringe pump:

- 1 start bit,

- 8 data bits,

- Parity: none,

- 1 stop bit,

- a baud rate of 9600 bits/s.

- Remote mode on the screen of the pump confirms a successful connection, indicating that the pump is being remotely controlled by a computer via a USB 2.0, Mini-B or RS-232 connection.

The Reglo ICC Command Serial Protocol

The Reglo ICC command protocol offers an array of commands for external control, categorized into distinct types for precise manipulation. These include communication management, operational modes and settings, control directives, setting configurations, calibration, and more.

There are two types of messages. Response messages sent from the pump to the PC and request messages sent from the PC to the pump. All messages are composed of a string of printable ASCII characters. Each message is terminated with a carriage return or a carriage return and a line feed.

The Reglo ICC command protocol used to control the Reglo ICC peristaltic pump is summarized below. More details can be found in the pump’s user manual.

Data Type Formats

| Data Type | Width | Unit | Range | Format |

|---|---|---|---|---|

| Direction | 1 | - | - | J = clockwise K = counter-clockwise |

| Discrete type 1 | 1 to 4 | - | 0 to 9999 | 1 to 4 characters in base 10. Unused digits are not returned. |

| Discrete type 2 | 4 | - | 0 to 9999 | 4 characters in base 10. Right-justified value. Unused digits to the left are zeros. |

| Discrete type 3 | 6 | - | 0 to 999999 | 6 characters in base 10. Right-justified value. Unused digits to the left are zeros. |

| Discrete type 4 | 10 | - | 0 to 4294967295 | 10 characters in base 10. Right-justified value. Unused digits to the left are zeros. |

| Discrete type 5 | 3 | - | 0 to 999 | 3 characters in base 10. Right-justified value. Unused digits to the left are zeros. |

| Discrete type 6 | 5 | - | 0 to 99999 | 5 characters in base 10. Right-justified value. Unused digits to the left are zeros. |

| Fractional type 1 | Variable | - | - | XXXX.DD Variable width of the integer portion (XXXX). Decimal point and two digits to the right (.DD) always provided. |

| Volume type 1 | 7 | mL | - | mmmmEse ⇒ m.mmm × 10^se: mmmm — 4 character mantissa Decimal point inferred after first character. E — 'E' character s — sign for the exponent : + or - e — single digit exponent |

| Time type 1 | 1 to 8 | 0.1s | 0 to 35964000 (0 to 999 hr) | 1 to 8 characters representing the time. Unused digits are not returned. |

| Time type 2 | 8 | 0.1s | 0 to 35964000 (0 to 999 hr) | 8 characters representing the time. Right-justified value. Unused digits to the left are zeros. |

Response Messages

A response message is a message sent from the pump to the PC in response to a request message sent by the PC. It can be in the form of a status or a data response.

A status response message is a single ASCII character that indicates whether the command was executed successfully or not. The different ASCII characters that indicate the execution status of the requested command are represented in the table below.

| ASCII Character | Definition | In Hex | In Base 10 |

|---|---|---|---|

| * | command executed successfully | 0x2a | 42 |

| # | command not executed successfully | 0x23 | 35 |

| + | positive response used for some commands | 0x2b | 43 |

| - | negative response used for some commands | 0x2d | 45 |

A data response is received from the pump when parameter values are requested by the PC. It is composed of one or more data parameter values delimited by spaces. Each data parameter in the response message is a data value returned by the pump in a format defined by the request message.

| Data Parameter 1 | [SP] | Data Parameter 2 | [SP] | … | Data Parameter n | [CR] | [LF] |

Request Messages

The request messages are messages sent from the PC to the pump. These should be answered by a response message from the pump.

A device control command (as shown below) is composed of a string of printable ASCII characters and terminated with a carriage return [CR] or a carriage return [CR] and a line feed [LF]. It is addressed to an individual pump/channel to get or set some particular parameters.

| Address (1-4) | Command code | Data Parameter 1 | [VB] | Data Parameter 2 | [VB] | … | Data Parameter n | [CR] | [LF] |

In the case of a bus of pumps that are "daisy-chained", the address is from 1 to 8 (maximum number of pumps being controlled at once). In the case where only one pump is being controlled, the address is from 1 to 4 corresponding to the number of channels being independently controlled, as presented in the control command just above.

The command string is typically one or two characters indicating the command type. The data parameters are optional values that may be provided when setting a parameter value. And finally, the vertical bar character delimits the data parameters.

Different commands can be addressed to the pump related to communications management, pump drive, operational modes and settings, calibration, and more. Some of these direct addressed commands are listed in the table below. More commands can be found and detailed in the operating manual.

| Command | Function | Set/Get | Pump Response |

|---|---|---|---|

| H | Start pump | Set | * - : channel setting not correct |

| I | Stop pump | Set | * |

| xI | Pause pumping (STOP in RPM or flow rate mode) | Set | * |

| J | Set rotation direction to clockwise | Set | * |

| K | Set rotation direction to counter-clockwise | Set | * |

| xD | Get rotation direction | Get | J : clockwise K : counter-clockwise |

| xM | Get pump/channel current mode | Get | L : RPM M : Flow Rate O : Volume at rate G : Volume over time Q : Volume+Pause N : Time P : Time+Pause |

| L | Set pump/channel to RPM mode | Set | * |

| M | Set pump/channel to Flow Rate mode | Set | * |

| O | Set pump/channel to Volume at rate mode | Set | * |

| G | Set pump/channel to Volume over time mode | Set | * - : channel setting not correct |

| S | RPM mode flow rate setting (0.01 RPM). Discrete type 3. | Set | * |

| S | Get current speed setting in RPM | Get | Fractional type 1 |

| f | Set RPM flow rate in volume/time mode (mL/min). Volume type 2 (Similar to type 1 without the 'E' character). | Set | Volume type 1 |

| f | Get current volume/time flow rate (mL/min) | Get | Volume type 1 |

| xP | Get pumping pause time | Get | Time type 1 |

| xY | Start calibration on a channel | Set | * |

| xZ | Cancel calibration | Set | * |

Different symbols are used to represent ASCII characters in the defined request messages. Some of these are presented in the table below.

| Symbol | Definition | In Hex | In Base 10 |

|---|---|---|---|

| [CR] | carriage return | 0x0d | 13 |

| [LF] | line feed | 0x0a | 10 |

| [SP] | space | 0x20 | 32 |

| [VB] | vertical bar | 0x7c | 124 |

| @ | '@' character | 0x40 | 64 |

Examples of Commands

In order to communicate with the pump, one should understand the different commands the pump takes and prepare the needed control computer command strings.

In the table below, a few examples of direct-addressed commands are presented and explained.

| Command | Definition | Pump Response | Definition |

|---|---|---|---|

| 1H[CR] | Start channel 1 | * | Command executed successfully |

| 4I[CR] | Stop channel 4 | * | Command executed successfully |

| 2xD[CR] | Get the direction of channel 2 | K[CR][LF] | Direction of rotation is counter-clockwise |

| 3J[CR] | Set the direction of rotation of channel 3 to clockwise | * | Command executed successfully |

| 1xM[CR] | Get the operational mode of channel 1 | L[CR][LF] | Current mode is RPM |

| 3G[CR] | Set the operational mode of channel 3 to volume over time | * | Command executed successfully |

| 1S[CR] | Get the drive speed of channel 1 | 22.50[CR][LF] | Response in the form of "fractional type 1". The drive speed is 22.5 RPM |

| 1S004500[CR] | Set the drive speed of channel 1 to 45 RPM. The speed setting has a resolution of 0.01 RPM (45 assigned as 4500) in the form of a "discrete type 3" with a width of 6 characters with unused digits to the left being zeros (=> 004500). | * | Command executed successfully |

| 3f[CR] | Get the pumping rate of channel 3 | 1275E+1[CR][LF] | Response in the form of a "volume type 1" (mmmmEse => m.mmm x10se):

|

| 3f1500-3[CR] | Set the pumping rate of channel 3 to 1.5 μL/min. Pumping rate setting in the form of "volume type 2" (mmmmse => m.mmm x10se). 1.5 µL/min = 1.500x10-3 mL/min, therefore:

| 1500E-3[CR][LF] | Response in the form of "volume type 1". |

How to Control the Reglo ICC Pump Using IsmaTerm ?

IsmaTerm is a software that allows one to control the Reglo ICC pump. It is a terminal emulation software that communicates with the pump via RS-232 serial port. IsmaTerm can be used to start and stop the pump, set and get the pump parameters, and program the pump operation. It is compatible with Windows operating systems and can be downloaded via this link.

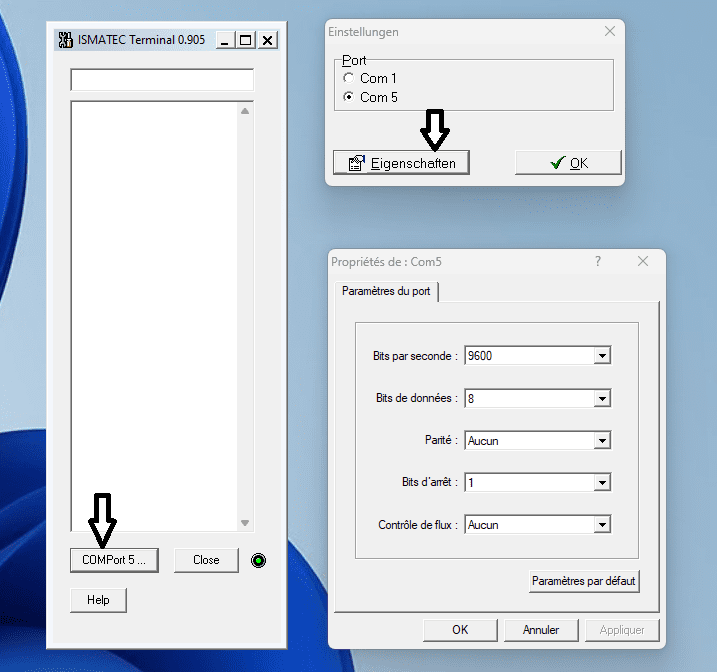

To communicate with the pump, launch the IsmaTerm software, select the COM port that corresponds to the pump and enter the settings of the port in order to change its characteristics (as can be shown in the figure below). The default baud rate is 9600 bits/s, with 8 data bits, 1 stop bit and no parity.

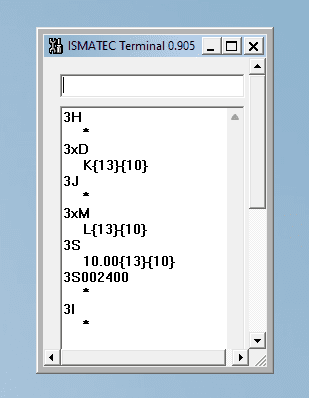

In the IsmaTerm window, one can type commands to control the pump and view its responses. These commands are case sensitive and must be followed by a carriage return (Enter key).

The IsmaTerm window presented below shows some messages sent to and received from the pump, allowing to start/stop the pump and set/get pump parameters. In this example, only channel 3 is being controlled. Each command sent to the pump receives a response from it (intended messages in the figure below).

The commands just presented in the IsmaTerm window are briefly explained in the table below.

| Command | Definition | Pump Response | Definition |

|---|---|---|---|

| 3H | Start channel 3 | * | Command executed successfully |

| 3xD | Get the direction | K{13}{10} | Direction of rotation is counter-clockwise {13} — carriage return [CR] {10} — line feed [LF] |

| 3J | Set the channel rotation direction to clockwise | * | Command executed successfully |

| 3xM | Get the operational mode of channel 3 | L{13}{10} | Current mode is RPM |

| 3S | Get the setting speed in RPM | 10.00{13}{10} | Fractional type 1. Rotation speed of 10 RPM. |

| 3S002400 | Set the speed to 24 RPM | * | Command executed successfully |

| 3I | Stop channel 3 | * | Command executed successfully |

A control command communicated to the pump is sometimes obtained after some calculations and conversions. It is therefore important to prepare all the needed commands before starting the external control of the pump.

Moreover, it is easier to have these control commands written and communicated to the pump via a set of codes (already prepared), using programming platforms such as Python and Matlab, than to write and send a command every now and then to the pump via a terminal program. These platforms allow not only an easier communication with the pump, but also, an easier external communication with a bus of pumps and allow writing a pumping program with loops, pauses, etc.

Quick start serial communication code snippets using Python and Matlab, that serve as a small introduction on how to communicate with the Reglo ICC pump via these two programming platforms, are provided and explained in the following.

How to Control the Reglo ICC Pump Using Python ?

The Reglo ICC pump can be controlled remotely using Python, offering greater flexibility and convenience for running complex pumping programs with loops, pauses, and varying speeds/flow rates. This approach is particularly useful when integrating multiple devices, as it allows for the automation of sequences involving all connected equipment.

In this section, we will show first how to open the serial port and send simple commands to the pump using Python. Then, a dedicated custom Python library that utilizes the Reglo ICC command protocol will be introduced, allowing one to open the serial port and send control command strings to the Reglo ICC pump. We’ll cover examples that show how to start and stop the pump, set speed, set rate, etc., providing a practical guide to using Python for controlling the Reglo ICC pump.

'''

------------------------------------------------

Writing/Reading Simple Commands to/from the Pump

------------------------------------------------

'''

import serial # Python module for serial communication

# Open the serial port with the data format corresponding to the Reglo ICC pump

ser = serial.Serial('COM5', 9600, parity=serial.PARITY_NONE, bytesize=8, stopbits=1, timeout=None, xonxoff=0, rtscts=0) # modify your COM#

### Start channel 3 of the pump

# Method 1

cmd = str(3) + 'H' + chr(13) # concatenate strings :

# 3 represents channel 3

# 'H' to start the channel

# 13 for the carriage return [CR]

ser.write(cmd.encode()) # write the concatenated string to ser

# Method 2

ser.write(f'{3}H{chr(13)}'.encode()) # write string literals to ser

read_data = ser.read(ser.in_waiting).decode()

# read all the available bytes from the serial port connection as a char vector

# The pump returns '*' after a successful execution of the command

### Read the rotation direction of channel 3

ser.write(f'{3}xD{chr(13)}'.encode()) # 'xD' to get the rotation direction

read_data = ser.read(ser.in_waiting).decode()

# The pump returns : K[CR][LF] --> counter-clockwise

### Change the rotation direction of channel 3 to clockwise

ser.write((str(3) + 'J' + chr(13)).encode()) # 'J' to set the direction to clockwise

read_data = ser.read(ser.in_waiting).decode()

# The pump returns '*' after a successful execution of the command

### Change the setting speed to 24 RPM

ser.write((str(3) + 'S002400' + chr(13)).encode())

# Setting speed has a resolution of 0.01 RPM so 24 RPM is assigned as 2400

# Discrete type 3 data has a width of 6 characters with unused digits to the left being zeros --> 002400

read_data = ser.read(ser.in_waiting).decode()

# The pump returns '*' after a successful execution of the command

### Stop channel 3 of the pump

ser.write((str(3) + 'I' + chr(13)).encode()) # 'I' to stop the channel

read_data = ser.read(ser.in_waiting).decode()

# The pump returns '*' after a successful execution of the command

Below, the custom Python library that utilizes the Reglo ICC command protocol is presented. This library enables the creation of complex pumping programs, including features such as pauses, loops, conditional logic, and more and enabling an easier control of a bus of pumps.

'''

------------------------------------------

Reglo ICC Peristaltic Pump Control Library

------------------------------------------

'''

import serial

import time

#---------------------------------------------------------------------------------#

# LIBRARY MANAGING THE COMMUNICATION WITH A REGLO ICC WITH 3 INDEPENDENT CHANNELS #

#---------------------------------------------------------------------------------#

class RegloICC:

# Initialize the pump

def __init__(self, COM):

self.COM = COM

# Open the serial port with the data format corresponding to the RegloICC pump

self.sp = serial.Serial(self.COM, 9600, parity=serial.PARITY_NONE, stopbits=serial.STOPBITS_ONE, bytesize=serial.EIGHTBITS)

self.direction = [0, 0, 0] # 0 = clockwise, 1 = counter-clockwise

self.mode = [0, 0, 0] # 0 = RPM, 1 = Flow Rate, 2 = Volume (over time), one can add here all other modes

self.speed = [0, 0, 0] # rotation speed for each channel in RPM mode

# Change the size of 'direction', 'mode' and 'speed' according to the total number of channels to control.

# In the case herein, 3 channels are being independently controlled

# Delete the pump

def __del__(self):

self.sp.close()

# Start the corresponding channel

def start_channel(self, channel):

command = f'{channel}H\r'.encode() # 'H' to start the channel

# \r for the carriage return [CR] required to tell the pump that the command is finished

self.sp.write(command) # write the command to the pump

time.sleep(0.1) # give the pump time to process the command after sending it before reading the response

return self.sp.read(self.sp.in_waiting).decode() # read the pump response

# Stop the corresponding channel

def stop_channel(self, channel):

command = f'{channel}I\r'.encode() # 'I' to stop the channel

self.sp.write(command)

time.sleep(0.1)

return self.sp.read(self.sp.in_waiting).decode()

# Set the rotation direction for a single channel

def set_direction(self, channel, direction):

if direction == 1:

command = f'{channel}K\r'.encode() # counter-clockwise

else:

command = f'{channel}J\r'.encode() # clockwise

self.sp.write(command)

self.direction[channel - 1] = direction # pyhton count starts from 0

time.sleep(0.1)

return self.sp.read(self.sp.in_waiting).decode()

# Get the rotation direction of a single channel

def get_direction(self, channel):

command = f'{channel}xD\r'.encode() # 'xD' to get the rotation direction

self.sp.write(command)

time.sleep(0.1)

# read the rotation direction from the corresponding channel

return self.sp.read(self.sp.in_waiting).decode()

# Set the speed for a single channel in RPM when in RPM mode

def set_speed(self, channel, speed): # in RPM, with speed less then 100

speed = max(min(speed, 100), 0) # speed between 0 and 100 RPM

speed_string = f'{int(speed):03d}{int((speed - int(speed)) * 100)}' # format speed explained below

command = f'{channel}S0{speed_string}\r'.encode()

self.sp.write(command) # set the speed for the corresponding channel

self.speed[channel - 1] = speed

time.sleep(0.1)

return self.sp.read(self.sp.in_waiting).decode()

#--------------------------------------------------------------------------------#

# SPEED_STRING EXAMPLE #

## Speed value : #

# speed = 123.456 #

# #

## Convert the integer part to a string with at least three digits : #

# integer_part = f'{int(speed):03d}'; ## --> Result: '123' #

# #

## Convert the decimal part to a string with two digits : #

# decimal_part = f'{int((speed - int(speed)) * 100)}'; ## --> Result: '45' #

# #

## Concatenate the two parts : #

# speed_string = f'{int(speed):03d}{int((speed - int(speed)) * 100)}'; #

## --> Result: '12345' representing 123.45 in fixed-point notation #

# #

## When the two strings are concatenated, the result is a string that represents #

## the original speed value in a fixed-point notation with three digits before #

## the decimal point and two digits after, without the decimal separator. #

#--------------------------------------------------------------------------------#

# Read out speed of a single channel in RPM when in RPM mode

def get_speed(self, channel):

command = f'{channel}S\r'.encode() # 'S' to get the setting speed in RPM

self.sp.write(command)

time.sleep(0.1)

return self.sp.read(self.sp.in_waiting).decode()

# Set the operational mode for a single channel (you can add all other modes)

def set_mode(self, channel, mode):

if mode == 0:

command = f'{channel}L\r'.encode() # RPM mode

elif mode == 1:

command = f'{channel}M\r'.encode() # Flow rate mode

else:

command = f'{channel}G\r'.encode() # Volume (over time) mode

self.sp.write(command)

self.mode[channel - 1] = mode

time.sleep(0.1)

return self.sp.read(self.sp.in_waiting).decode()

# Get the operational mode of a single channel

def get_mode(self, channel):

command = f'{channel}xM\r'.encode() # 'xM' to get the operational mode

self.sp.write(command)

time.sleep(0.1)

return self.sp.read(self.sp.in_waiting).decode()

#----------------------------------------------------------------------------#

# EXAMPLES ON HOW TO USE THE DEFINED CLASS TO CONTROL THE Reglo ICC PUMP #

#----------------------------------------------------------------------------#

### Initialize the pump with the specified COM port

pump = RegloICC('COM5') # Replace 'COM5' with your actual COM port

### Start channel 3

pump.start_channel(3)

### Get the rotation direction of channel 3

print(pump.get_direction(3))

### Set the rotation direction of channel 3 to clockwise

pump.set_direction(3, 0)

### Get the current operational mode of channel 3

print(pump.get_mode(3))

### Set the operational mode of channel 3 to RPM

pump.set_mode(3, 0)

### Get the current speed setting of channel 3

print(pump.get_speed(3))

### Set the setting speed of channel 3 to 24 RPM

pump.set_speed(3, 24)

### Stop channel 3

pump.stop_channel(3)

### Delete the pump object

del pump

How to Control the Reglo ICC Pump Using Matlab ?

In this section, Matlab code snippets will be presented, showing how to open the serial port, write and send control command strings to the pump. Next, a quick start adapter class is defined specifically for handling Reglo ICC commands.

We’ll walk through codelines that demonstrate how to perform common tasks such as starting/stopping the pump, setting speed, getting direction of rotation, etc.

%-------------------------------------------------

% Writing/Reading Simple Commands to/from the Pump

%-------------------------------------------------

%% Open the serial port with the data format corresponding to the Reglo ICC pump

sp = serialport('COM5',9600,'Parity','None','DataBits',8,'StopBits',1); % open the serial port

%% Start channel 3 of the pump (method 1)

cmd = strcat(num2str(3),'H',13); % concatenate strings :

% 3 represents channel 3,

% 'H' to start the channel

% 13 for the carriage return [CR]

write(sp,cmd,"uint8"); % write the concatenated string to sp

%% Start channel 3 of the pump (method 2)

fprintf(sp,'%s',strcat(num2str(3),'H',13)); % formats the concatenated string according to '%s' (character vector or string array) and writes it to sp

read_data = read(sp,sp.NumBytesAvailable,"char");

% read all the available bytes from the serial port connection as a char vector

%% Read the rotation direction of channel 3

cmd = strcat(num2str(3),'xD',13); % 'xD' to get the rotation direction

write(sp,cmd,"uint8");

read_data = read(sp,sp.NumBytesAvailable,"char");

%% The pump returns : K[CR][LF]. Change the rotation direction of channel 3 to clockwise

write(sp,strcat(num2str(3),'J',13),"uint8"); % 'J' to set the direction to clockwise

read_data = read(sp,sp.NumBytesAvailable,"char");

%% Change the setting speed to 24 RPM

write(sp,strcat(num2str(3),'S002400',13),"uint8");

% Setting speed has a resolution of 0.01 RPM so 24 RPM is assigned as 2400

% Discrete type 3 data has a width of 6 characters with unused digits to the left being zeros --> 002400

read_data = read(sp,sp.NumBytesAvailable,"char");

%% Stop channel 3 of the pump

write(sp,strcat(num2str(3),'I',13),"uint8"); % 'I' to stop the channel

read_data = read(sp,sp.NumBytesAvailable,"char");

%-----------------------------------------

% Reglo ICC Peristaltic Pump Adapter Class

%-----------------------------------------

%--------------------------------------------------------------------------------------%

% CUSTOM CLASS MANAGING THE COMMUNICATION WITH A REGLO ICC WITH 3 INDEPENDENT CHANNELS %

%--------------------------------------------------------------------------------------%

classdef RegloICC

%%% Define the class properties

properties

% Change the size of 'direction', 'mode' and 'speed' according to the total number of

% channels to control. In the case herein, 3 channels are being independently controlled

sp = []; % serial port

COM = ''; % input parameter: COM port to use for the pump

direction = [0 0 0]; % direction of rotation of each channel: 0 = clockwise, 1 = counter-clockwise

mode = [0 0 0]; % operational mode of each channel: 0 = RPM, 1 = Flow Rate, 2 = Volume (over time), one can add here all other modes (check Table 3)

speed = zeros(3,1); % rotation speed for each channel in case of RPM mode

end

%%% Define the class methods

methods

% Initialize the pump

function obj = RegloICC(COM)

obj.COM = COM;

obj.sp = serialport(obj.COM,9600,'Parity','None','DataBits',8,'StopBits',1); % open the serial port with the data format corresponding to the RegloICC pump

end

% Delete the pump

function obj = delete(obj)

delete(obj.sp);

obj.sp = [];

end

% Start the corresponding channel

function start_channel(obj,channel)

write(obj.sp,strcat(num2str(channel),'H',13),"uint8"); % 'H' to start the channel

% 13 for the carriage return [CR] required to tell the pump that the command is finished

pause(0.1); % give the pump time to process the command before reading the response

while obj.sp.NumBytesAvailable > 0 % clear the buffer

read(obj.sp, obj.sp.NumBytesAvailable, "char");

end

end

% Stop the corresponding channel

function stop_channel(obj,channel)

write(obj.sp,strcat(num2str(channel),'I',13),"uint8"); % 'I' to stop the channel

pause(0.1);

while obj.sp.NumBytesAvailable > 0

read(obj.sp, obj.sp.NumBytesAvailable, "char");

end

end

% Set the rotation direction for a single channel

function obj = set_direction(obj,channel,direction)

if direction == 1

write(obj.sp,strcat(num2str(channel),'K',13),"uint8"); % counter-clockwise rotation

pause(0.1);

while obj.sp.NumBytesAvailable > 0

read(obj.sp, obj.sp.NumBytesAvailable, "char");

end

else

write(obj.sp,strcat(num2str(channel),'J',13),"uint8"); % clockwise rotation

pause(0.1);

while obj.sp.NumBytesAvailable > 0

read(obj.sp, obj.sp.NumBytesAvailable, "char");

end

end

obj.direction(channel) = direction;

end

% Get the rotation direction of a single channel

function getDirection = get_direction(obj,channel)

write(obj.sp,strcat(num2str(channel),'xD',13),"uint8"); % 'xD' to get the rotation direction

pause(0.1);

getDirection = read(obj.sp,obj.sp.NumBytesAvailable,"char"); % read the rotation direction from the corresponding channel

end

% Set the speed for a single channel in RPM when in RPM mode

function obj = set_speed(obj,channel,speed) % in RPM, with speed 100

disp('Speed higher than maximum (100 RPM), reduced to maximum.');

end

speed = max(min(speed,100),0); % speed between 0 and 100 rpm

speedstring = strcat(sprintf('%03d',floor(speed)), num2str(floor((speed-floor(speed))*100))); % format speed explained below

obj.speed(channel) = speed; % set the speed for the corresponding channel

write(obj.sp,strcat(num2str(channel),'S0',speedstring,13),"uint8"); % write the speed to the corresponding channel

pause(0.1);

while obj.sp.NumBytesAvailable > 0

read(obj.sp, obj.sp.NumBytesAvailable, "char");

end

end

%----------------------------------------------------------------------------------%

% SPEEDSTRING EXAMPLE %

%% Speed value : %

% speed = 123.456 %

% %

%% Convert the integer part to a string with at least three digits : %

% integer_part = sprintf('%03d', floor(speed)); %% --> Result: '123' %

% %

%% Convert the decimal part to a string with two digits : %

% decimal_part = num2str(floor((speed - floor(speed)) * 100)); %% --> Result: '45' %

% %

%% Concatenate the two parts : %

% speedstring = strcat(integer_part, decimal_part); %

%% --> Result: '12345' representing 123.45 in fixed-point notation %

% %

%% When the two strings are concatenated, the result is a string that represents %

%% the original speed value in a fixed-point notation with three digits before %

%% the decimal point and two digits after, without the decimal separator. %

%----------------------------------------------------------------------------------%

% Read out speed of a single channel in RPM when in RPM mode

function getRPM = get_speed(obj,channel)

write(obj.sp,strcat(num2str(channel),'S',13),"uint8"); % 'S' to get the setting speed in RPM

pause(0.1);

getRPM = read(obj.sp,obj.sp.NumBytesAvailable,"char");

end

% Set the operational mode for a single channel (you can add all other modes)

function obj = set_mode(obj,channel,mode)

if mode == 0

write(obj.sp,strcat(num2str(channel),'L',13),"uint8"); % RPM mode

pause(0.1);

while obj.sp.NumBytesAvailable > 0

read(obj.sp, obj.sp.NumBytesAvailable, "char");

end

elseif mode == 1

write(obj.sp,strcat(num2str(channel),'M',13),"uint8"); % Flow rate mode

pause(0.1);

while obj.sp.NumBytesAvailable > 0

read(obj.sp, obj.sp.NumBytesAvailable, "char");

end

else

write(obj.sp,strcat(num2str(channel),'G',13),"uint8"); % Volume (over time) mode

pause(0.1);

while obj.sp.NumBytesAvailable > 0

read(obj.sp, obj.sp.NumBytesAvailable, "char");

end

end

obj.mode(channel) = mode;

end

% Get the operational mode of a single channel

function getMd = get_mode(obj,channel)

write(obj.sp,strcat(num2str(channel),'xM',13),"uint8"); % 'xM' to get the operational mode

pause(0.1);

getMd = read(obj.sp,obj.sp.NumBytesAvailable,"char");

end

end

end

%-------------------------------------------------------------------%

% Examples on how to use the defined class to control the Reglo ICC %

%-------------------------------------------------------------------%

%%% To start the communication and open the serial port %%%

% pump = RegloICC('COM5') % Replace 'COM5' with your actual COM port

%%% Start channel 3 %%%

% pump.start_channel(3)

%%% Get the rotation direction of channel 3 %%%

% pump.get_direction(3)

%%% Set the rotation direction of channel 3 to clockwise %%%

% pump.set_direction(3,0)

%%% Get the current operational mode of channel 3 %%%

% pump.get_mode(3)

%%% Set the operational mode of channel 3 to RPM %%%

% pump.set_mode(3,0)

%%% Get the current speed setting of channel 3 %%%

% pump.get_speed(3)

%%% Set the setting speed of channel 3 to 24 RPM %%%

% pump.set_speed(3,24)

%%% Stop channel 3 %%%

% pump.stop_channel(3)

%%% Delete pump %%%

% pump = delete(pump)

Conclusion

In this blog post, we’ve introduced the Reglo ICC (Independent Channel Control) peristaltic pump and explored the basics of its external control via two programming platforms, Python and Matlab, using the Reglo ICC communication command set. We hope this post serves as a valuable guide for researchers and engineers seeking to employ the Reglo ICC peristaltic pump in their microfluidics research and experiments.

Stay tuned for more insights, tutorials, and practical applications in our future posts. Until then, happy pumping and coding 💻!

📧 If you have any questions or feedback, please feel free to contact us at support@darwin-microfluidics.com.