Definition of a T-Junction in Microfluidics

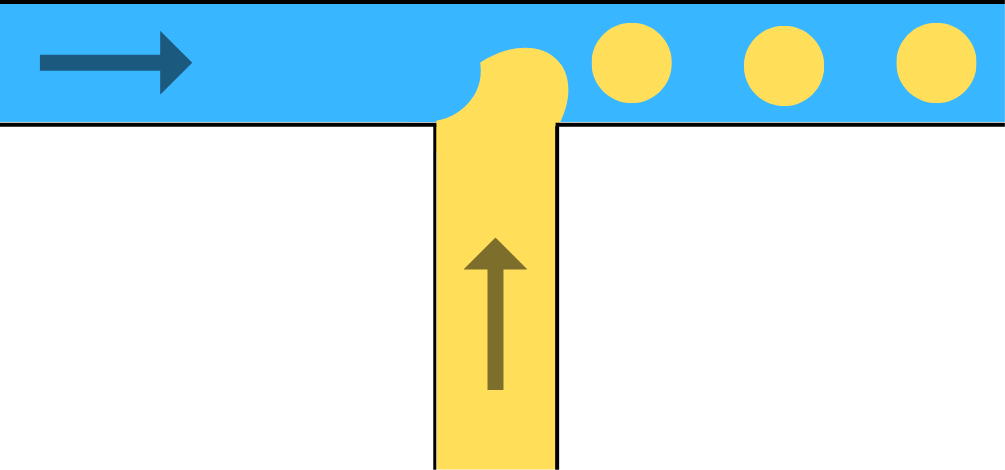

A T-junction in microfluidics is a channel intersection shaped like the letter “T” where one channel intersects perpendicularly with another channel. This setup is commonly used for controlled droplet generation, mixing, or flow manipulation in microfluidic devices.

Understanding the T-Junction

Imagine a tiny crossroads where two fluid streams meet – that’s essentially what a T-Junction is. It’s a point where one fluid stream (the continuous phase) intersects with another (the dispersed phase) at a right angle, forming a ‘T’ shape.

This intersection allows for the creation of droplets, bubbles, or particles, depending on the properties of the two fluids involved. The T-Junction is a critical component in many microfluidic applications, from chemical synthesis to biological assays.

The Mechanics of the T-Junction

So, how does a T-Junction work? Well, it’s all about fluid dynamics. When two fluid streams meet at the junction, the pressure and flow rates of the fluids determine how they interact. The dispersed phase fluid is typically squeezed into droplets by the shear force of the continuous phase fluid.

By adjusting the flow rates and pressures, it is possible to control the size and frequency of the droplets produced which allows for precise control over reactions and processes carried out within the droplets.

Materials Used in T-Junctions

T-Junctions in microfluidics are typically made from materials like polydimethylsiloxane (PDMS), a type of silicone, due to its optical transparency and biocompatibility. Other materials like glass or thermoplastics can also be used, depending on the specific requirements of the microfluidic system.

It’s worth noting that the material choice can affect the behavior of the fluids at the junction as hydrophobic materials for exapmle, can cause the dispersed phase fluid to bead up, while hydrophilic materials can cause it to spread out.

Applications of the T-Junction

The T-Junction has a wide range of applications in the field of microfluidics from lab-on-a-chip devices to microreactors for chemical synthesis.

Droplet-Based Microfluidics

One of its most common uses is in droplet-based microfluidics, where it’s used to create droplets of a precise size and frequency for use in assays, reactions, or other experiments. These droplets can act as tiny reaction chambers, allowing for high-throughput, parallelized experiments which greatly increases the speed and efficiency of experiments, and reduces the amount of reagents needed.

In a biological assay for example, each droplet can contain a single cell along with the necessary reagents, enabling the simultaneous analysis of thousands or even millions of cells within a device the size of a credit card.

Chemical Synthesis

The T-Junction is also commonly used in microreactors for chemical synthesis as scientists can carry out reactions within the created droplets under precisely controlled conditions. This can improve reaction efficiency and selectivity, while also enabling reactions that would be difficult or impossible in bulk solutions.

Advantages and Limitations of the T-Junction

Like any tool, the T-junction has its advantages and limitations.

Advantages

On the positive side, it’s a simple device that allows for precise control over droplet formation, and it’s relatively easy to fabricate and integrate into microfluidic systems. Another advantage is its versatility. The T-junction can be used with a wide range of fluids and can create droplets, bubbles, or particles depending on fluid properties, making it a flexible tool for various applications.

Limitations

Despite these advantages, the T-junction have some drawbacks. It can only produce droplets of a single size simultaneously, which can be restrictive for certain applications requiring a variety of droplet sizes. Additionally, it can be sensitive to changes in fluid properties, such as viscosity or surface tension, which can impact droplet formation.

Conclusion

In summary, the T-junction is a fundamental and versatile tool in microfluidics, crucial for tasks like droplet creation and fluid stream management. Its simplicity and effectiveness make it a staple in many microfluidic systems.