In microfluidics, the choice of material for components like connectors, fittings, and precision parts can have a significant impact on performance, reliability, and device longevity. Two high-performance thermoplastics that are often considered for these applications are Delrin (a homopolymer acetal) and PEEK (polyether ether ketone).

While Delrin offers excellent dimensional stability, low friction, and ease of machining, making it ideal for low- to medium-stress microfluidic components, PEEK provides exceptional heat resistance, chemical inertness, and mechanical strength, which are crucial in demanding environments or high-temperature processes.

Beyond microfluidics, Delrin and PEEK are widely used in industries such as aerospace, medical devices, automotive, where durability, precision, and performance under stress are essential. This article explores the unique properties and differences between Delrin and PEEK, helping you choose the right material for your microfluidic and industrial applications.

Delrin vs PEEK: Quick Comparison Table

The table below highlights the key properties of Delrin and PEEK, providing a side-by-side comparison of chemical resistance, mechanical characteristics, and other factors relevant to microfluidic and industrial applications.

| Property | Delrin | PEEK | Preferred Material |

|---|---|---|---|

| Chemical Resistance | Good | Excellent | PEEK |

| Coefficient of Friction | 0.25 | 0.32 | Delrin |

| Coefficient of Thermal Expansion (between 21°C and 100°C) | 12 × 10-5 /K | 10.3 × 10-5 /K | PEEK |

| Compressive Strength | 124 MPa | 138 MPa | PEEK |

| Cost | Relatively inexpensive | Expensive | Delrin |

| Density | 1.41 g/cm³ | 1.33 g/cm³ | - |

| Dielectric Strength | 15 kV/mm | 20 kV/mm | PEEK |

| Elongation | 75% | 40% | Delrin |

| Flexural Modulus | 2.8 GPa | 3.6 GPa | PEEK |

| Hardness (Rockwell M) | 94 | 100 | PEEK |

| Service Temperature (Continuous) | -40°C to 120°C | -40°C to 260°C | PEEK |

| Tensile Strength | 70 MPa | 110 MPa | PEEK |

| Thermal Conductivity | ~0.37 W/m·K | ~0.25 W/m·K | Delrin |

| Water Absorption | 0.25% | 0.1% | PEEK |

💡 Note: The values presented in this table are for reference purposes only. Actual properties may vary depending on the supplier, as factors such as size, grade, and brand can influence performance. Both Delrin and PEEK are often available with customized specifications to meet specific application requirements.

Delrin vs PEEK: Material Overview

To better understand how Delrin and PEEK perform in microfluidics and other domains, it is useful to examine their key properties, characteristics, and typical use cases.

About Delrin

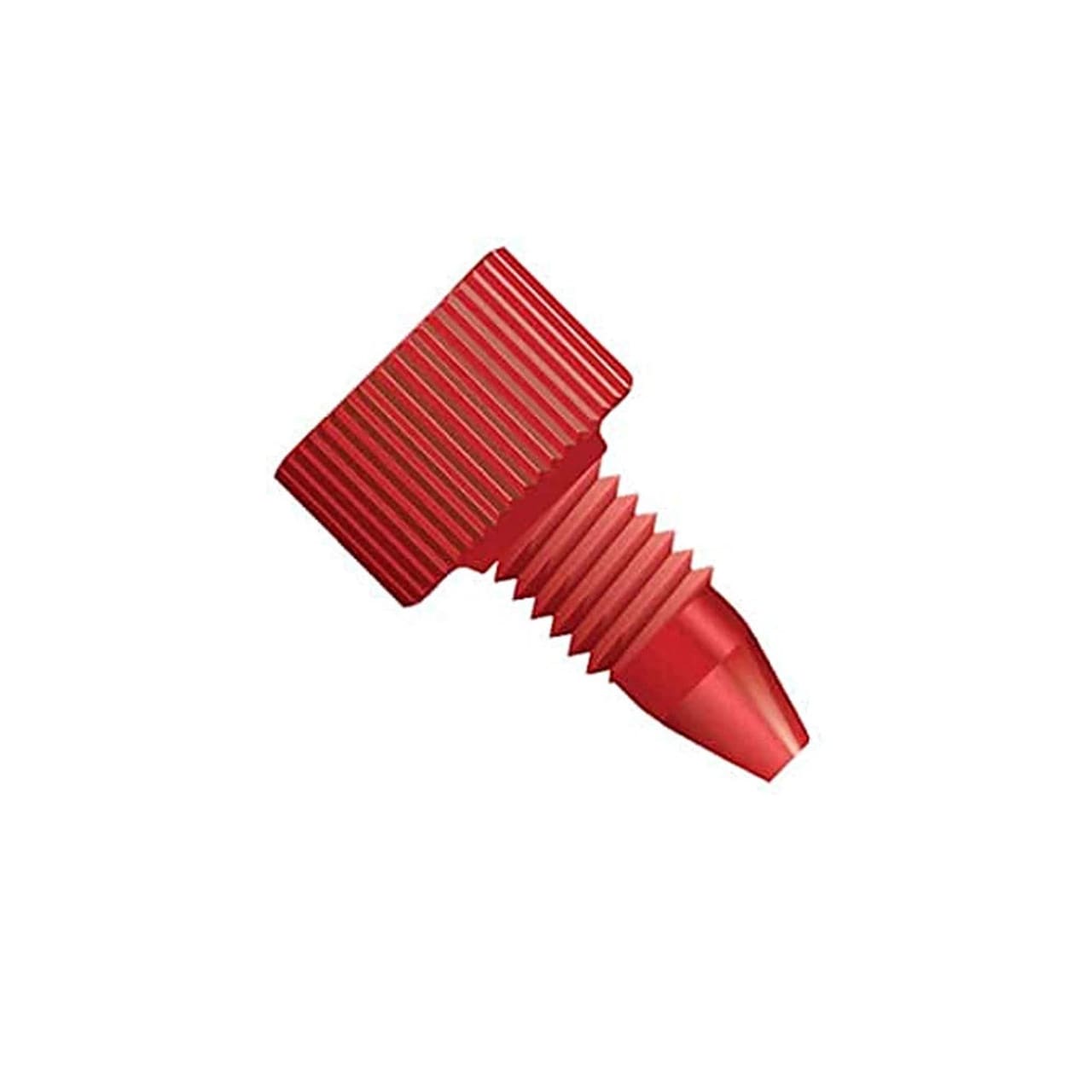

Delrin, also known as polyoxymethylene (POM), is a high-strength acetal homopolymer prized for its stiffness, dimensional stability, and low friction. Its durability and resistance to wear make it ideal for precision components, including microfluidic fittings, sliding parts, and mechanical assemblies. Delrin can be easily machined or molded into complex shapes, offering cost-effective performance for various applications including microfluidics, automotive parts, medical device housings, and industrial machinery.

About PEEK

Polyether ether ketone (PEEK) is a high-performance thermoplastic engineered for demanding environments. It offers exceptional chemical resistance, high tensile strength, and continuous-use thermal stability up to 260 °C. These properties make PEEK ideal for microfluidic systems exposed to aggressive solvents, high temperatures, or repeated sterilization cycles. Its applications extend into aerospace, medical implants, chemical processing, and high-performance industrial components.

Side-by-Side Comparison

To understand how Delrin and PEEK perform in microfluidics and other demanding applications, it is helpful to examine their mechanical, chemical, thermal, and cost characteristics side by side.

Mechanical Properties

PEEK exhibits superior tensile and compressive strength compared to Delrin, making it better suited for components subjected to high loads or repeated stress. Its stiffness and resistance to long-term creep allow precise, reliable performance under continuous mechanical strain.

Delrin, while still strong and rigid, is more suitable for moderate-load applications, where dimensional stability and low friction are key, such as sliding parts or low-pressure microfluidic fittings.

Chemical & Thermal Resistance

Delrin provides good chemical resistance and performs well with common solvents, fuels, and greases. However, it is less resistant to strong acids, bases, and high temperatures.

PEEK excels in these areas, tolerating aggressive chemicals and continuous exposure up to 260 °C, with short-term heat resistance even higher. Its low moisture absorption ensures stable dimensions in humid or aqueous environments, which is especially important for microfluidic components that must maintain accuracy and reliability during repeated fluid handling or sterilization processes.

Cost and Implementation

Delrin is significantly more cost-effective than PEEK, offering an economical solution for projects where extreme heat or chemical resistance is not required. Its ease of machining and low tool wear make it ideal for high-volume or precision parts in microfluidics and industrial applications.

PEEK, although more expensive, provides unmatched performance in high-temperature, chemically aggressive, or biocompatible applications, justifying the investment for specialized components in microfluidics, aerospace, or medical devices.

Typical Applications

Delrin is commonly used for low- to medium-stress microfluidic components, such as housings, fittings, and mechanical assemblies, as well as in automotive, medical devices, and industrial machinery where cost-efficiency and dimensional stability are important.

PEEK is preferred for high-performance microfluidic parts exposed to harsh chemicals, heat, or sterilization cycles, and for critical components in aerospace, medical implants, and chemical processing, where durability and reliability under extreme conditions are essential.

How to Choose Between Delrin and PEEK?

Choosing between Delrin and PEEK is less about which material is “better” overall and more about which aligns with the specific demands of your application. Below are scenario-based recommendations to guide your selection.

1. If chemical resistance and moisture stability are essential:

PEEK is the preferred choice due to its excellent resistance to strong acids, bases, and aggressive solvents. Also, its low moisture absorption ensures consistent mechanical performance and dimensional stability, making it ideal for microfluidic components that must endure repeated fluid exposure or sterilization.

2. If mechanical strength and wear resistance are required:

PEEK outperforms Delrin in tensile strength, compressive strength, and long-term fatigue resistance, making it more suitable for load-bearing or high-stress components.

3. If operating conditions involve higher temperatures:

PEEK outperforms Delrin in thermal stability, maintaining its mechanical integrity up to 260°C. Delrin, while suitable for moderate temperatures, begins to lose strength beyond 120°C, making PEEK more suitable for high-temperature or sterilization environments.

4. If cost is a deciding factor:

Delrin is more economical and easier to machine, making it ideal for budget-sensitive projects, while PEEK’s higher price reflects its superior mechanical performance, thermal stability, and chemical resistance.

5. If low friction is critical:

Delrin offers a naturally low coefficient of friction, making it ideal for applications with sliding components, precision mechanisms, or microfluidic parts where smooth motion is essential.

👉 In short:

- Choose Delrin when you need a cost-effective, low-friction, and mechanically stable material for moderate conditions.

- Choose PEEK when you require extreme heat resistance, chemical stability, high mechanical performance, or biocompatibility.

Delrin vs PEEK: Frequently Asked Questions

A closer look at common questions helps clarify which material is best suited for specific microfluidic and industrial applications.

Q1: Which material has better chemical resistance, Delrin or PEEK?

PEEK offers superior chemical resistance compared to Delrin and can withstand strong acids, bases, and aggressive solvents, making it suitable for harsh chemical environments in microfluidics and industrial setups.

Q2: Which material is stronger mechanically, Delrin or PEEK?

PEEK generally provides higher tensile and compressive strength, making it more suitable for load-bearing components or parts exposed to high stress, while Delrin is strong enough for medium-duty applications.

Q3: Which material tolerates higher temperatures, Delrin or PEEK?

PEEK can operate continuously up to around 260°C and handle short-term peaks even higher, whereas Delrin is typically limited to around 120°C, making PEEK better for high-temperature applications.

Q4: Which is more cost-effective between Delrin and PEEK?

Delrin is the more economical choice, while PEEK is significantly more expensive due to its high-performance properties.

Q5: Which material is better for low-friction applications, Delrin or PEEK?

Delrin has a naturally low coefficient of friction and is ideal for components requiring smooth sliding or precision movement, such as gears and rollers.

Q6: Are Delrin and PEEK suitable for biocompatible or medical applications?

PEEK is generally used in medical implants due to its certified biocompatibility, while Delrin is suitable for non-implantable medical equipment or disposable housings.

Q7: Which material, Delrin or PEEK, performs better in humid environments?

PEEK’s low water absorption ensures excellent dimensional stability even in humid or wet environments, whereas Delrin absorbs slightly more moisture, which may affect tight-tolerance components over time.

💡 Conclusion

Delrin and PEEK are two high-performance engineering plastics widely used for fittings, connectors, and precision components in microfluidics and other demanding industries. Understanding their strengths and limitations helps you choose the best material for your application—balancing factors like mechanical performance, chemical compatibility, temperature resistance, and cost to ensure long-term reliability and efficiency.

Stay tuned for more deep dives into material choices for microfluidics, comparing tubing, connectors, and other component materials to help you make the best selection 🔬!

📧 If you have any questions or feedback, please feel free to contact us at contact@darwin-microfluidics.com.

🔗 References

- FOW Mould. Delrin vs PEEK: The Main Differences.

https://www.immould.com/delrin-vs-peek/ - JACO Products. PEEK vs Delrin: Properties and Applications.

https://jacoproducts.com/material-comparison/peek-vs-delrin/ - OTiVIC. Delrin vs PEEK: Which Plastic Suits Your Needs?.

https://otivic.com/delrin-vs-peek/ - Duo-Tec Tool. Delrin-Acetal & PEEK.

https://www.duotectool.com/delrin-acetal-peek - PTS Make. What is Delrin?.

https://www.ptsmake.com/what-is-delrin/ - AZoM. PEEK (Polyether Ether Ketone) Properties.

https://www.azom.com/properties.aspx?ArticleID=1882 - BearingWorks. PEEK Data Sheet.

https://www.bearingworks.com/uploaded-assets/pdfs/retainers/peek-datasheet.pdf