Oils are essential in microfluidic droplet generation, serving as either the continuous phase that surrounds dispersed droplets or as the dispersed phase itself, forming droplets within an aqueous medium. Their versatile properties enable precise control over droplet formation and stability. Whether stabilizing emulsions for biological studies or facilitating reactions in chemical synthesis, oils are critical to the success of microfluidic processes.

In this blog, we’ll explore the various types of oils used in droplet generation, their defining properties and key considerations to optimize microfluidic droplet generation experiments.

Oils in Droplet Generation

Oils play a vital role in microfluidics. Their immiscibility with water and ability to form stable interfaces make them ideal for creating well-defined discrete microenvironments. With tunable properties like viscosity, density, and interfacial tension, oils provide exceptional control over droplet size and stability, outperforming other liquids in droplet formation and phase separation.

In droplet generation, oils such as silicone and fluorinated types are especially valuable due to their chemical inertness, ensuring compatibility with sensitive biological and chemical reagents. Whether acting as the continuous or dispersed phase, oils deliver consistent performance, making them indispensable in applications like diagnostics, cell encapsulation, and high-throughput screening.

Types of Oils Used in Droplet Generation

A variety of oils are used in microfluidic systems, each offering unique properties that make them suited for specific applications. From highly specialized fluorinated oils to more accessible options like silicone or mineral oils, the choice of oil can significantly impact droplet formation and stability. Below is an overview of the most commonly used oils in microfluidics and their key advantages.

Fluorinated Oils

Fluorinated oils, including well-known options like FC40 and HFE7500, are widely regarded as essential in microfluidic droplet generation, often serving as the continuous phase. These oils have exceptional characteristics—such as low surface tension, chemical inertness, biocompatibility, and high resistance to contamination. Fluorinated oils, including Fluo-Oils from Emulseo, are particularly valuable in high-precision biological settings like drug development and lab-on-a-chip systems, where precise droplet size and stability are crucial.

💡 The production of the widely used fluorinated oils, Novec™ 7500 and Fluorinert™ FC-40, will be discontinued this year due to increasing regulatory pressures from the European Chemicals Agency (ECHA) and other regulatory bodies. These regulations aim to address the environmental and potential human health concerns associated with PFAS (per- and polyfluoroalkyl substances), the core compounds in these oils. While they have been essential in microfluidic applications, it’s important to consider reliable alternative solutions as the industry adjusts to these changes.

Mineral Oils

Mineral oils, derived from the distillation of crude petroleum, are colorless, odorless liquids used in microfluidic droplet generation due to their affordability and stability. Their high viscosity makes them particularly effective for applications requiring slower and more controlled droplet formation.

Although mineral oils are valuable in industrial and scientific applications, their use in sensitive biological contexts is often limited because of potential toxicity. Despite this, highly purified forms of mineral oil are utilized in cosmetics and microbiology.

Silicone Oils

Silicone oils, composed of silicon, oxygen, and carbon compounds, are commonly used in microfluidic droplet generation for their outstanding chemical stability and low surface tension. Their non-toxic and inert nature makes them ideal for sensitive applications that demand non-reactive materials.

A major advantage of silicone oils is their stability at high temperatures, allowing them to perform consistently in processes with thermal variations. Additionally, their low surface tension facilitates efficient droplet formation and enhances stability within microfluidic systems, making them a reliable choice for diverse applications.

Vegetable Oils

Vegetable oils, such as sunflower, olive, corn, and rapeseed oils, are plant-derived alternatives used in microfluidic droplet generation. These oils are valued for their eco-friendly nature and biocompatibility, making them particularly suitable for applications in biological studies.

Their natural origin and safety profile have contributed to their growing popularity in microfluidic applications, especially those prioritizing sustainability and non-toxic materials.

| Types of Oil | Advantages | Common Uses |

|---|---|---|

| Fluorinated Oils | ||

| Mineral Oils | ||

| Silicone Oils | ||

| Vegetable Oils |

The compatibility of oils with different materials varies significantly and plays a crucial role in microfluidic system performance. Using an oil that is incompatible with the materials in your system can lead to chemical degradation, compromised performance, or even system failure.

💡 For more details, refer to the chemical compatibility chart for mineral, silicone, and fluorinated oils, providing a quick reference on how these oils interact with various materials.

Properties of Oils

Oils are essential in microfluidics, with their selection playing a critical role in droplet formation, stability, and overall system performance. Key properties such as viscosity, interfacial tension, and density directly influence the efficiency and precision of droplet generation, making them vital considerations for successful microfluidic applications.

Viscosity

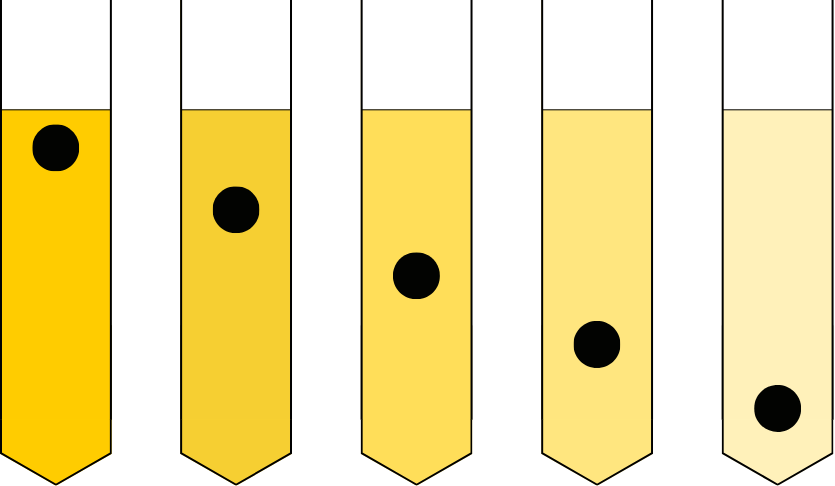

Viscosity is a crucial factor in droplet formation, as it determines the flow behavior of the oil within the microfluidic system. Oils with high viscosity can slow down droplet generation, enabling better control over the size and uniformity of larger droplets. Conversely, low-viscosity oils, like fluorinated oils, facilitate faster droplet formation, which is advantageous for creating small, uniform droplets. Therefore, the optimal viscosity depends on the specific application.

Density

The density of the oil directly impacts phase separation and the overall stability of droplet formation. Oils with a density close to that of the dispersed phase offer better control and more consistent droplet generation. If the oil’s density is too high or too low compared to the dispersed liquid, it can result in issues like unstable droplet formation or inadequate phase separation (such as creaming or sedimentation), which can negatively affect droplet size and stability.

Interfacial Tension

The interfacial tension between the oil and the other phase is a key factor in droplet stability. A low interfacial tension promotes the formation of smaller, more stable droplets by reducing the energy required to create and maintain the droplet. Fluorinated oils, known for their low interfacial tension, are often preferred in microfluidics because they facilitate stable droplet generation and improve overall process efficiency.

Some Applications of these Oils in Microfluidics

The diverse properties of oils make them suitable for a wide range of microfluidic applications. Depending on the type of oil and the desired emulsion, specific surfactants are required to stabilize the droplets and ensure optimal performance.

Below, three tables showing some applications of fluorinated, mineral, silicone, and vegetable oils, along with their compatible surfactants, are presented. These tables are adapted from the work of Jean-Christophe Baret (Lab Chip, 2012, 12, 422–433), providing a valuable reference for selecting the right oil-surfactant combination for your microfluidic application.

| Surfactant | HFE/Novec 7500 | FC40 |

|---|---|---|

| PF-octanol | - | Micro PIV |

| PF-decanol | - | PCR in droplets |

| PFPE-COOH | Splitting droplets Droplet detection | Electrocoalescence |

| PFPE-COONH4 | Multiple emulsions | Cells in droplets Droplet hydrodynamics Chemical reaction |

| PFPE-PEG | Directed evolution Picoinjector PCR and diagnostics DNA amplification Sorting microorganisms Yeasts in droplets | Cells in droplets Dropspot Coalescence Chemical gradients Droplet separation Electrocoalescence |

| PFPE-DMP | Cells in droplets Coalescence | Bacteria in droplets |

| No surfactant | Bacteria Antibiotics | Bacteria Antibiotics |

| Surfactant | DC200 | PDMS | AR20 |

|---|---|---|---|

| Triton X-100 | - | - | PCR |

| SDS (in water) | - | Oil-in-water emulsification | - |

| ABIL EM90 | - | - | Directed evolution |

| No surfactant | Chemical compound storage Emulsification | Raman measurement | - |

| Surfactant | Mineral Oil | Vegetable Oil |

|---|---|---|

| Span80 | Protein expression Droplet patterns Molecular exchange Cell encapsulation Chemical reactions Electrically assisted emulsification Electrowetting in emulsification | - |

| Monolein | - | Bilayers (squalane) |

| Oleic acid | Tip streaming | - |

| C12E8 | Tip streaming | - |

| N-butanol | Interfacial rheology | - |

| ABIL EM90 | PCR in droplets Directed evolution | - |

| No surfactant | Droplet hydrodynamics PCR in droplets | Droplet hydrodynamics (sunflower oil) |

💡 Conclusion

Oils are indispensable in microfluidic droplet generation, offering the versatility and precision required for various applications, from biological research to material synthesis. Selecting the right oil is crucial for the success of experiments, as each option comes with its own set of advantages and challenges. Understanding the properties and applications of different oil types will help make informed choices that enhance system performance and stability.

Stay tuned for upcoming content featuring in-depth explorations of innovative microfluidic techniques, practical alternatives to regulatory challenges, and expert tips for optimizing droplet generation processes. Until then, don’t pop your drop 🫧!

📧 If you have any questions or feedback, please feel free to contact us at contact@darwin-microfluidics.com.